g006530

Figure 93

1.

Cutting edge

3.

Wear/slot forming

2.

Curved area

4.

Crack

Checking for Bent Blades

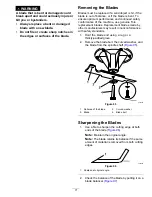

1.

Disengage the blade-control switch (PTO), move

the motion-control levers to the N

EUTRAL

-

LOCK

position, and engage the parking brake.

2.

Shut off the engine, remove the key, and wait

for all moving parts to stop before leaving the

operating position.

3.

Rotate the blades until the ends face forward

and backward.

4.

Measure from a level surface to the cutting

edge, position

A

, of the blades (

g000975

Figure 94

1.

Measure here from blade

to hard surface

2.

Position A

5.

Rotate the opposite ends of the blades forward.

6.

Measure from a level surface to the cutting edge

of the blades at the same position as in step

above.

Note:

The difference between the dimensions

obtained in steps

and

must not exceed 3

mm (1/8 inch).

Note:

If this dimension exceeds 3 mm (1/8

inch), the blade is bent and must be replaced.

70

Summary of Contents for Z Master Professional 5000 Series

Page 13: ...decal136 5508 136 5508 1 Belt routing 13...

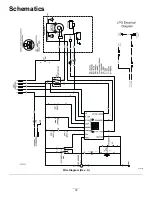

Page 78: ...Schematics g021490 Wire Diagram Rev A 78...

Page 79: ...Notes...