Raising the Front of the

Machine

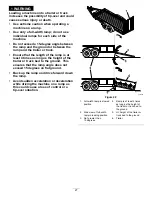

If the front of the machine needs to be raised, use the

very front edge as show in

.

Important:

To prevent damage to the steering

mechanism, ensure that the very front edge of the

machine is used for jacking points.

g028320

Figure 23

Lubrication

Greasing the Bearings

Service Interval:

Every 25 hours—Grease all the

lubrication points.

Grease Type:

No. 2 lithium grease

1.

Park the machine on a level surface, and

disengage the blade-control switch.

2.

Ensure that the parking brake is engaged,

shut off the engine, remove the key, and wait

for all moving parts to stop before leaving the

operating position.

3.

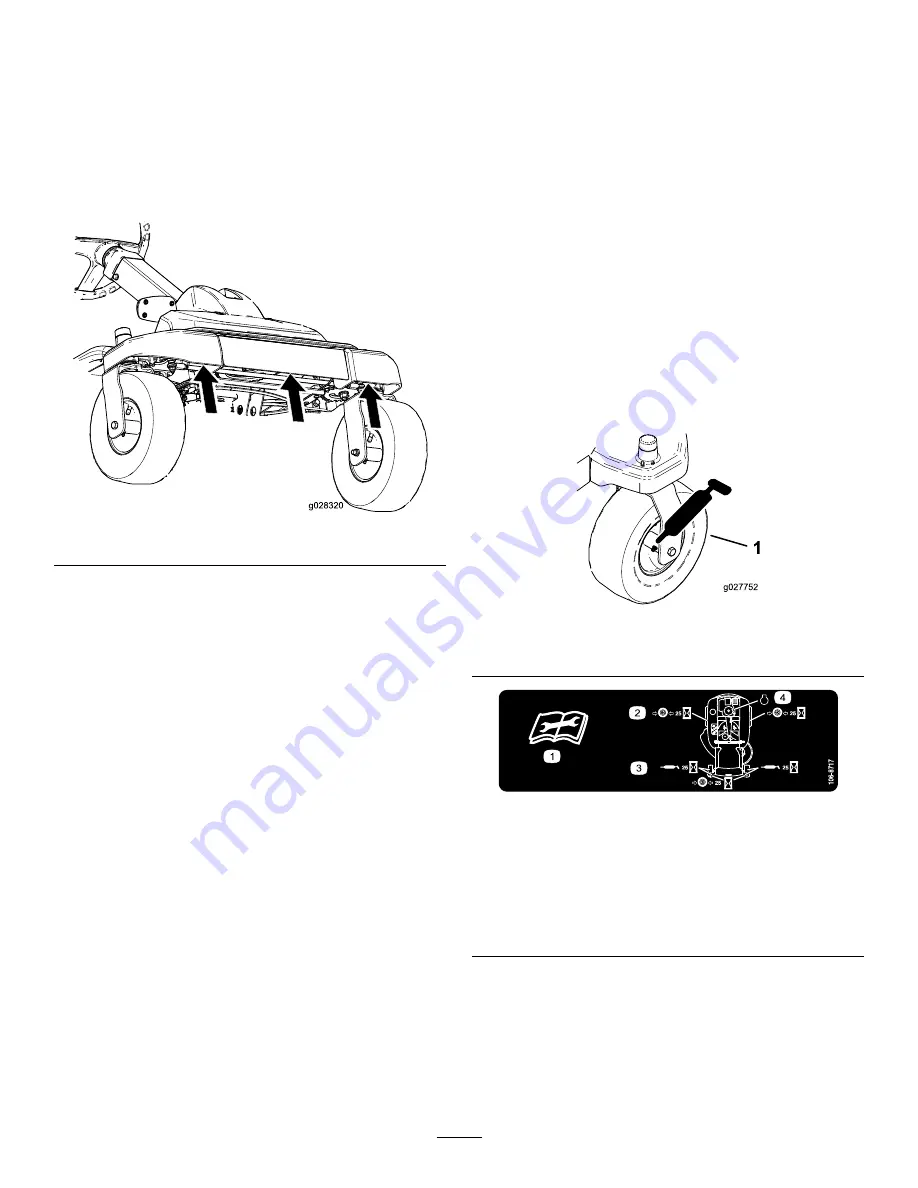

Clean the grease fittings (

and

) with a rag.

Note:

Make sure to scrape any paint off the

front of the fitting(s).

g027752

Figure 24

1.

Front caster tire

decal106-8717

Figure 25

Located on the seat-pan underside

1.

Read the instructions

before servicing or

performing maintenance

3.

Grease every 25 operating

hours

2.

Check the tire pressure

every 25 operating hours

4.

Engine

4.

Connect a grease gun to each fitting (

and

).

5.

Pump grease into the fittings until grease begins

to ooze out of the bearings.

30

Summary of Contents for TimeCutter SW 5000

Page 52: ...Schematics g027754 Electrical Diagram Rev A 52 ...

Page 53: ...Notes ...

Page 54: ...Notes ...

Page 55: ...Notes ...