clutch should be engaged, the dash indicator light

glowing and the jackshaft turning when the lift

cylinder is fully retracted. As the lift cylinder is

extended, the light should go out, the clutch disen-

gage and the jackshaft stop turning. Correct the

problem if the safety switches are not operating

correctly.

3.

With the operator on the seat, the engine running,

the clutch switch engaged, the cutting units lowered

and the lift cylinder fully retracted, the reels should

turn and the dash indicator light should glow. If the

reels do not turn and the light does not glow, an

adjustment to the cutting unit interlock switch may

be necessary.

A.

Stop the engine and set the parking brake.

B.

Make sure the cutting units are completely

lowered and the lift cylinder is fully retracted.

C.

Locate the cutting unit interlock switch on the

left side of the machine on the bottom of the

hydraulic cylinder.

D.

Turn the screw out until the switch is activated.

Check continuity when the switch is activated.

E.

Check operation and repeat adjustment, if nec-

essary.

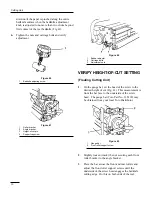

ADJUST THE STEERING COLUMN

1.

Raise the hood.

2.

Remove the capscrew securing the steering column

to the frame bracket.

3.

Adjust the steering column to the desired operating

position and reinstall the capscrew.

TOWING THE TRACTION UNIT

In case of emergency, the Reelmaster 216-D can be

towed for a short distance. However, Toro does not rec-

ommend this as a standard procedure.

IMPORTANT Do not tow the machine faster than

3–4.8 kmh (2–3 mph) because the drive system

may be damaged. If the machine must be

moved a considerable distance, transport it on

a truck or trailer.

1.

Turn the by-pass valve on pump counterclockwise

until it is fully open.

2.

Before starting the engine, close the by-pass valve

securely by rotating it clockwise. Do not exceed

7–11 Nm (5–8 ft-lb) torque. Do not start the

engine when the valve is open.

TRAINING PERIOD

Before mowing with the Reelmaster, The Toro Company

suggests you find a clear area and practice starting and

stopping, raising and lowering the cutting units, turning,

etc. This training period will help the operator gain con-

fidence in the performance of the Reelmaster.

20

Operating

Figure 21

1.

Steering column

2.

Frame bracket

Figure 22

1.

By-pass valve

Summary of Contents for reelmaster 216

Page 24: ...Figure 28 Figure 29 Figure 30 Figure 31 24 Maintenance ...

Page 34: ......

Page 35: ......

Page 36: ......