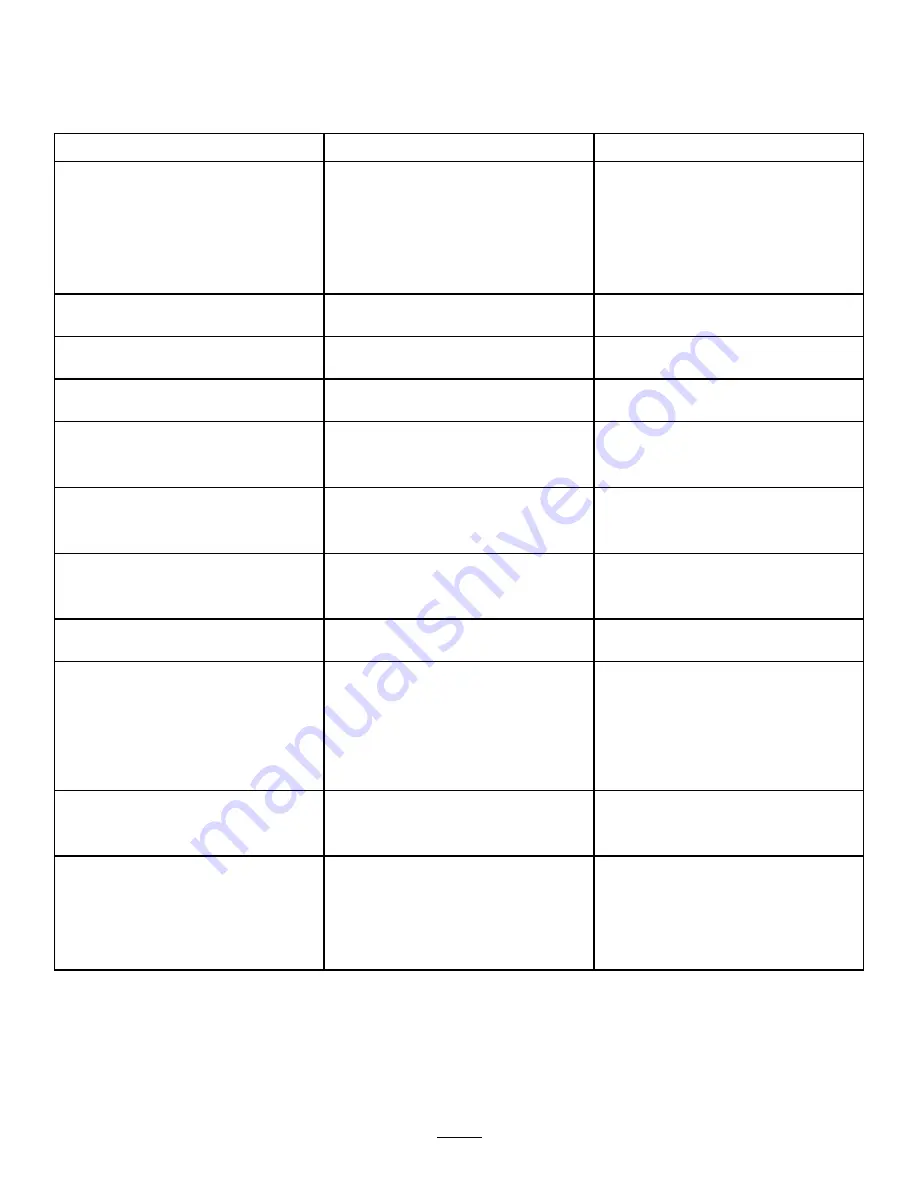

Troubleshooting

Note:

If the console computer malfunctions or needs repair, you can resume spraying in manual mode by unplugging

the cables form the rear of the console computer. You can then control the system using the center console controls.

Problem

Possible Cause

Corrective Action

1. The fuse on the back of the console

computer is blown.

1. Replace the fuse.

2. The battery connections are loose.

2. Secure the battery connections.

3. The power switch is not operating

properly.

3. Repair or replace the power switch.

No display lights with the power on

4. There is a problem with the processor

board assembly.

4. Have an Authorized Distributor replace

the processor board assembly.

All keyboard lights are on at the same time

1. There is a problem with the face plate

sub assembly.

1. Have an Authorized Distributor replace

the face plate sub assembly.

You cannot enter a digit using the keyboard

1. There is a problem with the face plate

sub assembly.

1. Have an Authorized Distributor replace

the face plate sub assembly.

An indicator on a key does not illuminate

1. There is a problem with the face plate

sub assembly.

1. Have an Authorized Distributor replace

the face plate sub assembly.

1. The battery connections are loose.

1. Secure the battery connections.

The console computer displays a flashing

Cal whenever you start the engine

2. The battery is not providing sufficient

voltage.

2. Check the battery voltage.

1. The battery connections are loose.

1. Secure the battery connections.

The console computer displays a flashing

Cal whenever you turn the master switch

to the On or Off position

2. The battery is not providing sufficient

voltage.

2. Check the battery voltage.

1. The battery connections are loose.

1. Secure the battery connections.

The console computer displays a flashing

Cal whenever you change the speed

2. The battery is not providing sufficient

voltage.

2. Check the battery voltage.

One display digit has one or more missing

segments

1. There is a problem with the LCD

display board assembly.

1. Have an Authorized Distributor replace

the LCD display board assembly.

1. The pins on the speed sensor cable

connector and the plug on the back of

the console computer are loose.

1. Have an Authorized Distributor repair

or replace the connector or the plug on

the back of the console computer.

2. The pins and the sockets on the speed

sensor cable are dirty.

2. Clean the pins and sockets on the

speed sensor cable connectors.

The speed display reads 0

3. There is a problem with the speed

sensor switch assembly.

3. Have an Authorized Distributor replace

the speed sensor switch assembly.

1. The wheel drive setting is not set to

SP3.

1. Set the wheel drive setting to SP3.

The speed is inaccurate or unstable

2. The Speed Cal number is incorrect.

2. Enter the correct Speed Cal number.

1. The Speed Cal is zero.

1. Enter the correct Speed Cal number.

2. The wheel drive setting is not set to

SP3.

2. Set the wheel drive setting to SP3.

The rate reads 0000

3. The Total Volume is not registering the

flow.

3. Ensure that the flowmeter is pointing

in the direction of flow and is operating

properly.

19