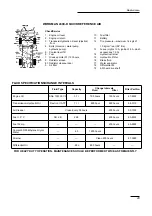

Locations For Selected

Maintenance Procedures

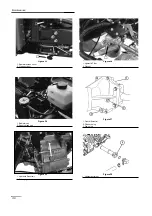

Figure 27

1. Dust Cup & Baffle

2. Filter Element

3. Air Cleaner Body

Figure 28

1. Engine Oil Drain Plug

Figure 29

1. Engine Oil Filter

Figure 30

1. Fuel filter/water Separator

2. Fuel pump

Figure 31

1. Drain Plug

2. Filter Canister

Figure 32

1. Fuel pump cover

2. Filter

3. Gasket

35

Maintenance

➀

➁

➀

➀

➀