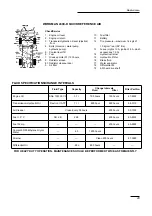

GREASING BEARINGS AND

BUSHINGS

The vehicle has (18) grease fittings that must be

lubricated regularly with No. 2 General Purpose

Lithium Base Grease. If the machine is operated

under normal conditions, lubricate all bearings and

bushings after every 100 hours of operation. More

frequent lubrication is required if used for heavy

duty vehicle operations.

The grease fitting locations and quantities are: Tie

rod ends (4) (Fig. 16); Front ball joints (4) (Fig. 16);

Rear drive shafts (6) (Fig. 17); Front pivot bushings

(2) (Fig. 18); Mid drive shaft—4 Wheel drive only

(3) (Fig. 19); Pedal Pivots (4) (Fig. 20); Steering

shaft (1) (Fig. 21) and Accelerator Arm (1) (Fig. 22).

IMPORTANT: When greasing drive shaft univer-

sal shaft bearing crosses, pump grease until it

comes out of all 4 cups at each cross.

1. Wipe the grease fitting clean so foreign matter

cannot be forced into the bearing or bushing.

2. Pump grease into the bearing or bushing.

3. Wipe off excess grease.

Figure 16

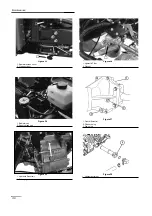

Figure 17

Figure 18

31

Maintenance

Before servicing or making adjustments to the

machine, stop the engine, set the parking brake and

remove key from the ignition switch. Any load

material must be removed from bed or other attach-

ment before working under raised bed. Never

work under a raised bed without positioning safety

support on a fully installed cylinder rod. Always

rotate the safety support to the down position

before working under the raised bed.

WARNING