Greensmaster Flex 18/21

Page 7 – 21

Cutting Unit

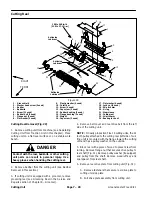

C. If cutting unit is equipped with a groomer, remove

LH groomer side plate (see Groomer Reel Bearing

Replacement in the Service and Repairs section of

Chapter 8 – Groomer).

D. Locate and retrieve three (3) spacers (items 4

and 5) from between reel drive plate and side plate.

7. Remove front and rear rollers from cutting unit (see

Roller Removal in this section).

8. Support reel weight on right side of the cutting unit to

prevent it from falling. Remove two (2) cap screws and

flat washers that secure weight. Remove reel weight

from cutting unit.

NOTE: The reel bearing lock nut has left hand threads.

9. Block reel with a piece of wood to prevent reel from

turning. Remove reel bearing lock nut from right side of

reel.

10.Remove cap screw, flat washer and lock nut that se-

cures grass shield to RH side plate.

IMPORTANT: Support reel to prevent it from falling as

side plate is removed.

11. Remove two (2) shoulder bolts and square nuts that

secure RH side plate to crossmember (Fig. 32). Slide

RH side plate and pitch arm from reel shaft.

12.Slide cutting reel from the LH side plate and cutting

unit.

13.If necessary, remove LH side plate and pitch arm

from crossmember and grass shield.

14.Refer to Cutting Reel Service in this section for infor-

mation on reel inspection and wear sleeve and v–ring

seal service.

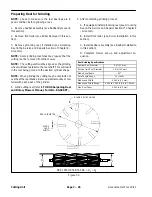

Cutting Reel Installation (Fig. 29)

1. Use a flat level surface or a stable work bench to

install cutting reel.

2. If separated, attach LH side plate to crossmember

with two (2) shoulder bolts and square nuts (Fig. 32).

Torque shoulder bolts from 210 to 240 in–lb (23.7 to

27.1 N–m). Make sure that LH pitch arm is installed on

bushing on side plate.

3. Apply antiseize lubricant to bearing journals of cut-

ting reel.

4. Make sure that wear sleeve and v–ring seal are prop-

erly installed on both ends of reel shaft (see Cutting Reel

Service in this section).

5. Apply grease to lips of grease seals in side plates to

ease reel installation.

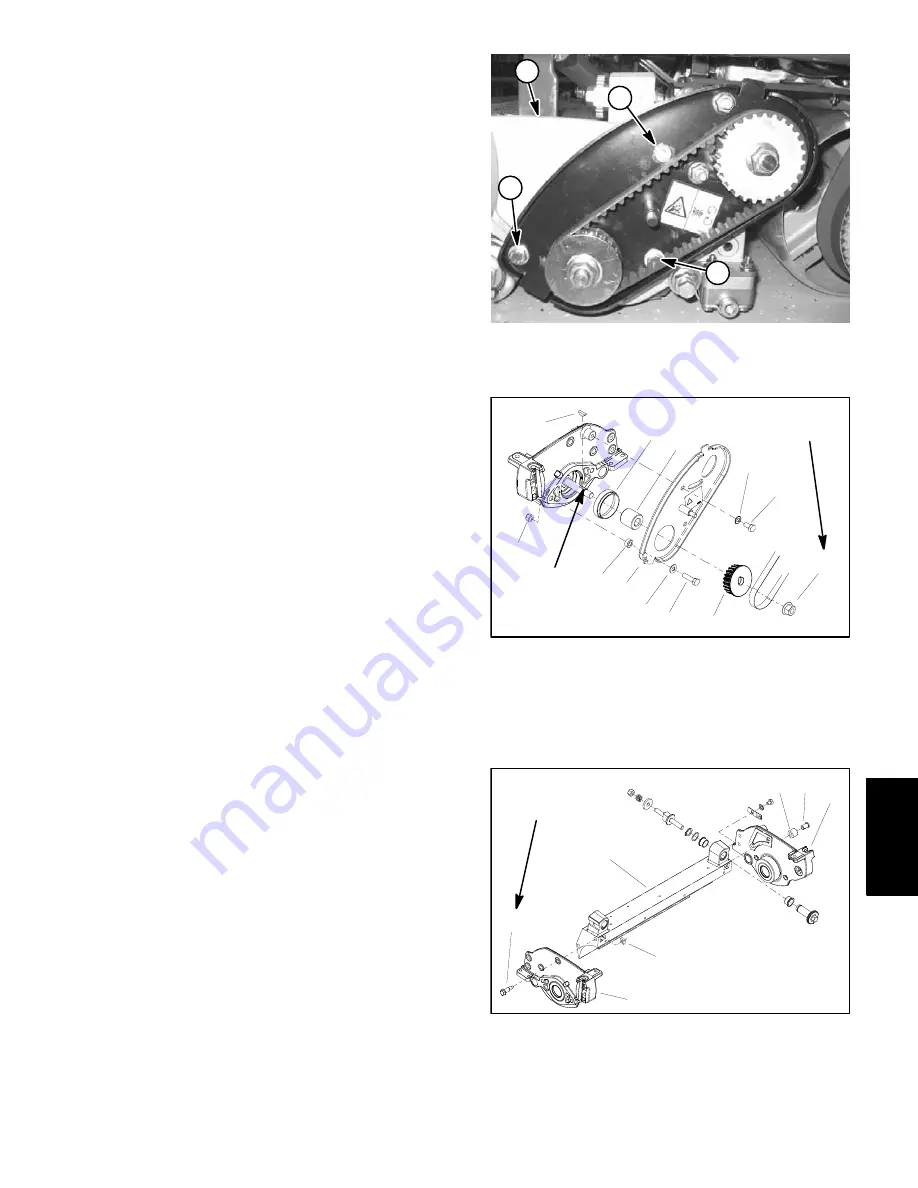

1. Cap screw w/lock washer

2. Cap screw w/flat washer

3. LH cutting reel sideplate

Figure 30

2

2

1

3

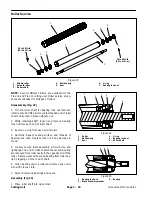

1. Flange

nut

2. Drive pulley (22 tooth)

3. Lock nut (2 used)

4. Spacer (2 used)

5. Spacer

6. Lock

washer

7. Cap

screw

8. Reel drive plate

9. Woodruff

key

10. Cap screw (2 used)

11. Flat washer (2 used)

12. Seal spacer

Figure 31

5

3

2

1

4

6

8

7

9

10

11

12

Antiseize

Lubricant

40 to 50 ft–lb

(54 to 68 N–m)

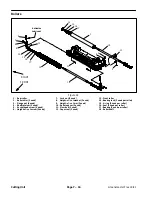

1. Crossmember

2. Shoulder bolt (4 used)

3. RH side plate

4. Square nut (4 used)

5. LH side plate

6. Nylon

bushing

7. Rubber

bushing

Figure 32

3

2

1

4

5

6

7

210 to 240 in–lb

(23.7 to 27.1 N–m)

Cutting Unit

Summary of Contents for 04022 Greensmaster Flex 21

Page 2: ...Greensmaster Flex 18 21 This page is intentionally blank ...

Page 4: ...Greensmaster Flex 18 21 This page is intentionally blank ...

Page 58: ...Greensmaster Flex 18 21 Page 5 10 Electrical System This page is intentionally blank ...

Page 83: ...Greensmaster Flex 18 21 Page 7 13 Cutting Unit This page is intentionally blank Cutting Unit ...

Page 85: ...Greensmaster Flex 18 21 Page 7 15 Cutting Unit This page is intentionally blank Cutting Unit ...

Page 111: ...Greensmaster Flex 18 21 Groomer Page 8 15 This page is intentionally blank Groomer ...