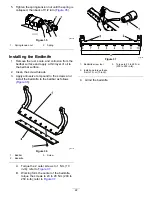

Adjusting the Shop Roller

Assemblies

Model 03192 Only

Before you lower the cutting units to the shop floor or

remove them from the traction unit, lower the shop

roller assemblies to protect the reel and bedknife

blades from hard surface contact.

Before operating the cutting units, install them to the

machine, raise the cutting units, and raise the shop

roller assemblies to prevent them from touching the

grass and interfering with operation.

1.

Remove the cotter pin from the clevis pin that

secures the shop roller bracket to the side plate.

2.

Position the shop roller assembly as needed:

•

Lower the shop roller brackets before the

cutting unit is lowered to the shop floor or

removed from the traction unit (

).

g341821

Figure 13

1.

Clevis pin (always installed

in the top square hole in

the side plate)

3.

Shop roller assembly (in

lowered/shop position)

2.

Side plate

•

Raise the shop roller brackets after the

cutting unit is raised to the operating position

(

g341820

Figure 14

1.

Clevis pin (always installed

in the top square hole in

the side plate)

3.

Shop roller assembly (in

raised/operating position)

2.

Side plate

Note:

Ensure that the clevis pin is always

installed in the top square hole in the side

plate.

3.

Secure the shop roller bracket to the clevis pin

with the cotter pin.

4.

Repeat this procedure on the opposite end of

the cutting unit, and for all other cutting units as

needed.

11