g035802

Figure 14

1.

Holes (beacon bracket)

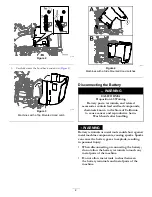

Installing the Switch

1.

On the main control panel at the rear of the control

pad, remove and discard the blanking plug.

2.

Pull out the switch connector containing orange and

red / orange and black wires and plug in the switch.

3.

Press the switch into the cutout until it clicks into place

(

).

g034461

Figure 15

1.

Switch

Completing the Installation

Installing the Bulkhead Panel

1.

Align the 4 holes in the bulkhead panel with the 4 clip

nuts on the chassis; refer to

in

Bulkhead Panel (page 3)

.

2.

Secure the bulkhead panel to the chassis of the machine

with the 4 bolts, 4 lock washers, and 4 flat washers; refer

to

in

Removing the Bulkhead Panel (page 3)

.

3.

Torque the bolts to 7.7 to 11.6 N∙m (68 to 103 in-lb).

Connecting the Battery Cables

WARNING

Incorrect battery cable routing could damage the

machine and cables, causing sparks. Sparks can

cause the battery gases to explode, resulting in

personal injury.

•

Always disconnect the negative (black) battery

cable before disconnecting the positive (red)

cable.

•

Always connect the positive (red) battery cable

before connecting the negative (black) cable.

1.

Connect the positive battery cable to the battery post;

refer to

Disconnecting the Battery (page 2)

2.

Align the insulator cover of the battery-cable terminal

and close the cover; refer to

(page 2)

.

Note:

Closing the cover will tighten the battery cable

terminal from the positive battery post.

3.

Connect the negative battery cable to the battery post;

refer to

in

Disconnecting the Battery (page 2)

.

4.

Align the insulator cover of the battery-cable terminal

and close the cover; refer to

in

the Battery (page 2)

.

Note:

Closing the cover will tighten the battery cable

terminal from the negative battery post.

Applying the Serial Label and Lowering

the Hood

1.

Apply the serial label to the left frame rail, adjacent to

the machine serial label.

2.

Close and secure the hood; refer to

(page 1)

.

3.

Rotate the lock 90° clockwise to the LOCK position;

refer to

Opening the Hood (page 1)

.

6