Summary of Contents for DECO 13a

Page 1: ...QUICK REFERENCE DECO 13a en 300417 Printed in Switzerland Copyright 1999 2008 ...

Page 28: ...QUICK REFERENCE DECO 13A en 300417 04 08 28 1 13 KINEMATICS ...

Page 45: ...QUICK REFERENCE DECO 13A en 300417 04 08 45 4 DRIVE ...

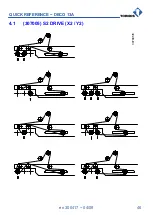

Page 46: ...QUICK REFERENCE DECO 13A en 300417 04 08 46 4 1 307005 S2 DRIVE X2 Y2 307005f3 ...

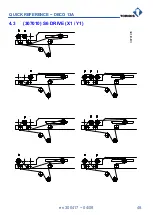

Page 48: ...QUICK REFERENCE DECO 13A en 300417 04 08 48 4 3 307010 S6 DRIVE X1 Y1 307010f3 ...