81

Sharpening

Once you have created the shape of the edge, it is an easy task to quickly re-sharpen the

tool. The sharpening should be done on your Tormek machine for the best finish and to

ensure that the edge is not overheated. Make the three settings noted on the Profile Label

carefully and you will obtain exactly the same shape every time even when the stone wears

and decreases in diameter.

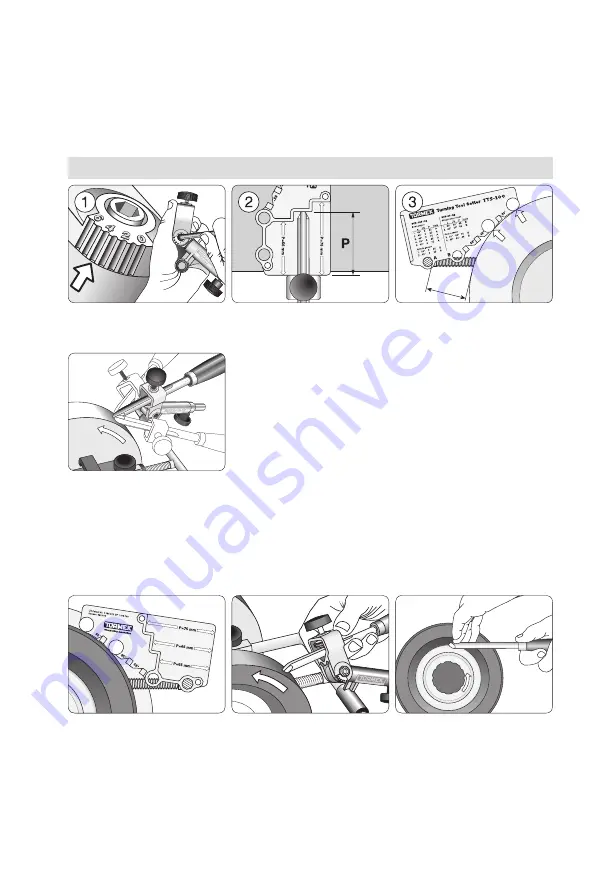

Set the jig, JS.

Mount the tool with

a fixed protrusion, P.

Set the Universal Support.

Use hole A or hole B.

Sharpen with a light pressure

and swing the tool from side to

side. Since the shape is exactly

replicated and the edge is just

touched up, the sharpening

takes just 20–30 seconds.

Move the Universal Support to

the honing wheel and make the

same setting with the Setter.

Hone by swinging the tool

from side to side. You now

have an extra fine finish.

Polish the flute and remove

the burr on the Profiled Leather

Honing Wheel LA-120.

Honing

Honing and polishing the bevel and the flute to a finer finish will make the sharpness more

durable. Also, use the Setter and jig for this operation and you are sure that you are honing

to exactly the same shape as the sharpening plus you do not risk rounding off the very tip

of the edge.

These three factors determine the geometry of a gouge