10

Power Unit

Specifications

:

High pressure

8500psi

Low pressure

1450psi

High flow

0.45GPM

Low flow

2.10GPM

Hydraulic Oil

32# anti wear hydraulic oil

Tank capacity

8Gallon

AC motor

115V/60Hz, 2HP 1750RPM

•

Totally enclosed fan cooled motors

•

Motors have continuous horsepower ratings

•

Adjustable relief valve preset at factory

•

Reservoirs plumbed for vertical mount

•

8 gallon rectangular reservoir

General Safety Information:

1.Follow all local electrical and safety codes, as well as the National Electrical Code (NEC) and the Occu- pational Safety

and Health Act (OSHA).

2.For Single Phase Motors use 3-wire cords with 3-prong grounding type plugs.

3.Make certain that wire size is adequate for horsepower requirements.

NOTE: Voltage drop increases with the length of power cord. Larger wire diameter may be required.

4.Nameplate voltage must be available at the motor when it is operating under load. Avoid voltage drop by using adequate

wiring.

5.Replace or repair damaged or worn power cord imme- diately.

6.The use of 3-prong single phase adapters in Canada is prohibited by the Canadian Electrical Code.

7.DOUBLE CHECK ROTATION! Motor rotation is clock- wise facing fan end of motor.

8.On start-up, jog the motor to prime the pump to insure adequate lubrication. After inlet line is full, motor may be operated at

full speed.

CAUTION:Never run the pump dry.

9.Keep all lines as short as practical.

10.Never exceed the maximum operating pressure.

11.Do not overtighten fittings, bolts, etc., as this can dam- age the units.

12.Provide adequate cooling for the hydraulic oil so as not to allow oil and/or component damage due to excessive

temperatures. Excessively high operating temperatures can be hazardous and may cause property damage and/or personal

injury.

Maintenance

1. Keep the reservoir filled with hydraulic fluid. Use a good quality automatic transmission fluid (ATF). To fill the

reservoir with clean oil, use a clean funnel fitted with a fine mesh wire screen. Do not use a cloth strainer. Most pump/fluid

motor failures, valve malfunctions, and short unit life can be traced directly or indirectly to dirt or other foreign materials

(water, chips, lint, etc.) entering or already in the hydraulic system.

2. Make frequent inspection of hydraulic fluid and change if contaminated.

3. Regularly inspect hydraulic hoses and fittings for wear or leakage.

4. Keep the unit clear of dirt and foreign materials.

5. Keep electrical connections clean.

WWW.TMGINDUSTRIAL.COM

P10/19

Toll Free:1-877-761-2819

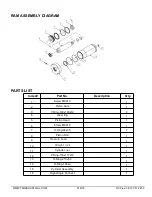

Tank Cap

Tank

AC motor

Pressure gauge

Control handle