172-65528A-01 (VS3-E/VS3-P/VS3-EP) 8 Jul 2015

4

Features

1. Precision-ground float and 3-point seating provide the tightest seal.

2. All stainless steel construction provides outstanding corrosion resistance.

3. The air vent has no hinges or levers: the only moving part is the polished float,

which eliminates concentrated wear and provides long service life.

4. Simple construction with few parts allows for easy maintenance.

5. The air vent is small and light.

Operation

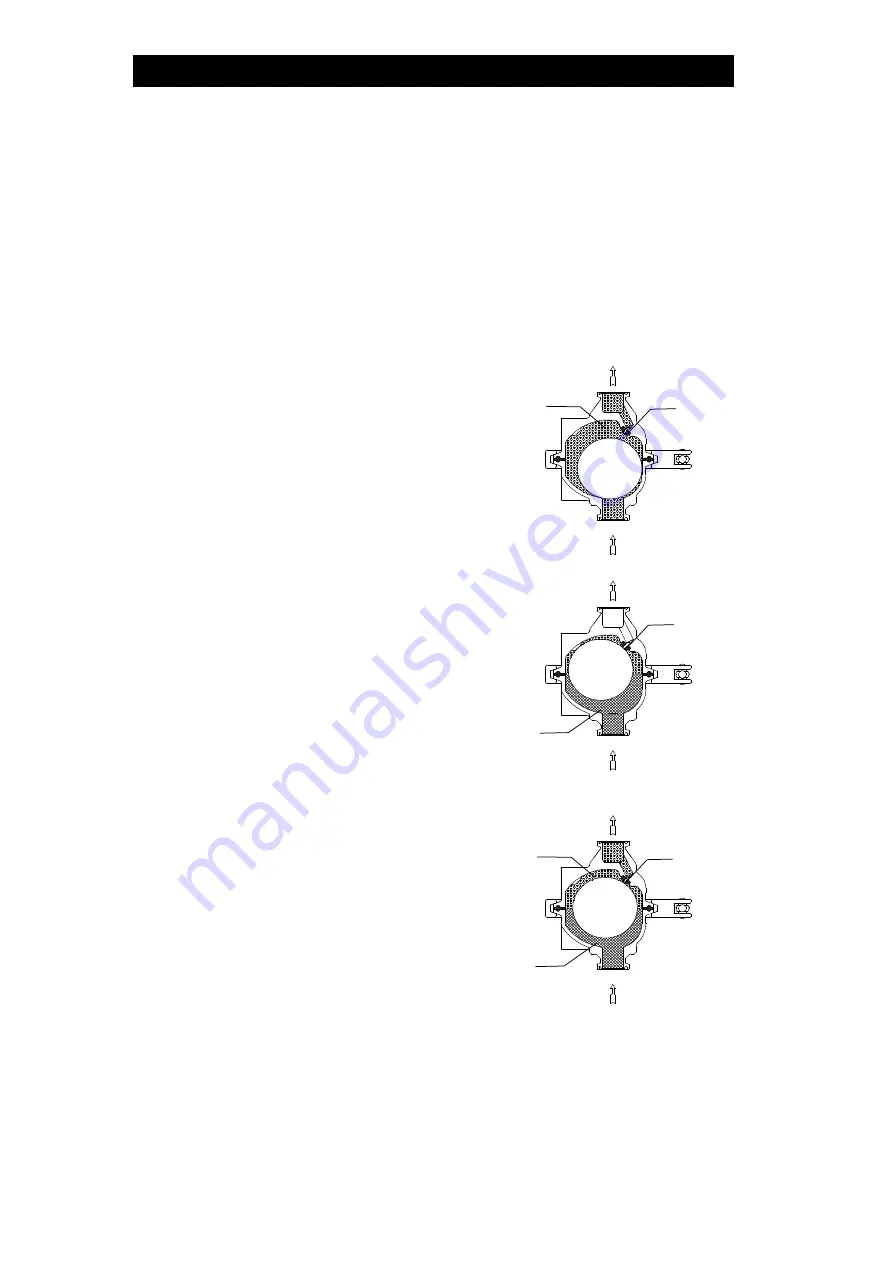

1.

When water starts to flow through the

piping, air trapped within the piping is

pushed along by the water pressure and

enters the air vent. At first, because the

float is positioned in the lower part of the

air vent, the valve is fully open and the air

passes through the valve seat and is

discharged rapidly through the vent.

2.

When the air has been discharged and

water begins to enter the air vent, the

float starts to rise due to buoyancy. This

pushes it upwards against the valve

opening, thus closing the air vent.

If there is a rapid rise in water level

(caused by rapidly opening a shut-off

valve, etc.), a small amount of water may

leak with discharged air immediately

before the air vent closes.

3.

When more air is trapped in the air vent

due to the inflow of water having closed

the valve, the water level in the air vent is

forced down and consequently the level of

the float falls, opening the valve. Air can

now again escape through the air vent,

and as it does so the level of the water

rises, pushing the float upwards again to

close the valve. In this way the VS3 series

automatically adjusting air vents

constantly respond to the flow of air.

4.

When draining the piping, the air vent

automatically opens to introduce air and

remove water more easily (preventing a

vacuum from forming in the piping).

Valve seat

Valve seat

Valve seat

Air

Air

Water

Water