172-65742MA-01 (CT20/CT20D) 7 Oct 2021

11

Disassembly/Reassembly

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Use the following procedures to remove components. Use the same procedures in

reverse to reassemble. (Installation, inspection, maintenance, repairs, disassembly,

adjustment and valve opening/closing should be carried out only by trained

maintenance personnel.)

For details of the actuator and the electro-pneumatic digital positioner, refer to the

respective instruction manuals issued by the manufacturer.

NOTE: Be sure to coat all threaded portions of the valve seat and bolts with anti-seize.

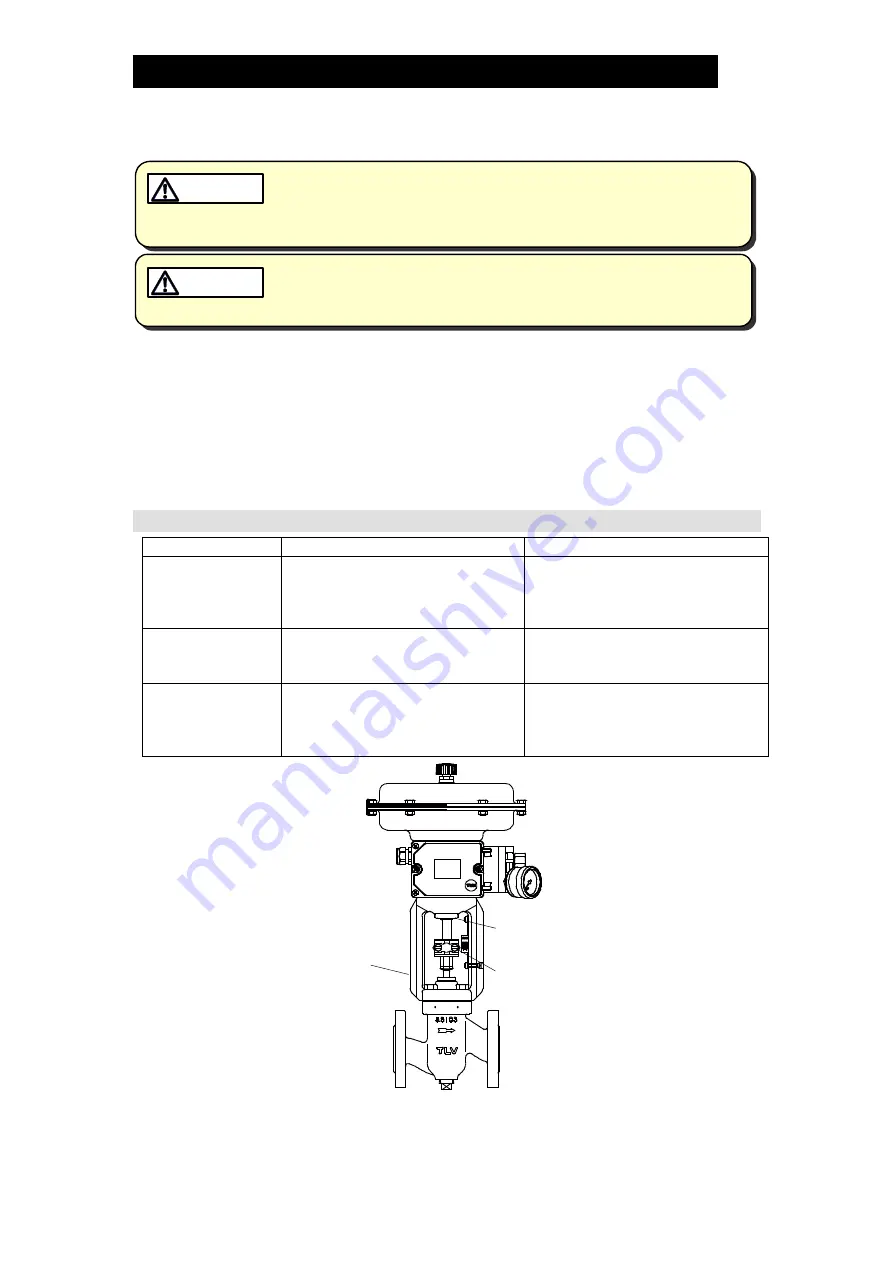

Removing/Reattaching the Actuator (Positioner)

Part

During Disassembly

During Reassembly

Stem Bracket Bolt

Loosen the stem bracket bolt and

remove the stem bracket clamps

connecting the actuator stem and

stem connector nut

Consult the table of tightening

torques and tighten to the proper

torque

―

When an input signal is sent to

the positioner, the actuator stem

will ascend

―

Fixing Nut

Remove the fixing nut connecting

the actuator and the valve bonnet

while keeping the actuator stem in

the raised position

Consult the table of tightening

torques and tighten to the proper

torque

Fixing Nut

Stem Bracket Clamps

Valve Bonnet