English

English

© Titan Tool Inc. All rights reserved.

13

12. Replace the thrust washers if worn. If the pump housing

assembly is replaced, replace the thrust washers as well.

NOTE: If any of the gears are worn and require replacement,

check the grease in the gear housing for metal

particles or shavings. Remove the contaminated

grease. Replace the grease that has been removed

with fresh Lubriplate GR-132 grease.

13. Coat each of the thrust balls with a generous amount of

grease. Install the thrust balls — one in the gear housing bore

and one in the pump housing bore.

14. Coat the gear assembly with fresh Lubriplate GR-132 grease.

Insert the gear assembly into the bore in the pump housing,

pinion end first.

15. Generously coat both faces of each of the crankshaft thrust

washers with grease.

16. Place the thick thrust washer onto the crankshaft up against

the gear hub. Next, place the thin thrust washer up against

the thick washer on the crankshaft.

17. Place the housing gasket over the gear housing dowel pins.

18. Carefully place the pump housing assembly in front of the

gear housing assembly, lining up the gear housing dowel pins

with their corresponding holes in the pump housing. Slide

the pump housing onto the gear housing until there is no gap

between the housings and gasket.

ImPORTANT: Do not force the pump housing and gear housing

together.

19. Locate the four socket screws and lock washers that secure

the pump housing to the gear housing. The longer screws

(2.25”) are fastened into the top internal holes. The shorter

screws (2”) are fastened into the bottom external bosses.

20. Using a 1/4” hex wrench, snug and tighten the socket screws

in a crossing pattern. Torque to 200–230 in.-lbs.

21. If the slider, slider housing, and fluid section were removed,

reinstall by following the steps in the “Replacing the Slider and

Slider Housing” procedure in this section.

22. Position the front cover over the pump housing. Secure the

front cover using the four front cover screws.

23. Using a 7/8” open-end wrench, attach the fluid hose to the

fitting on the back of the fluid section. Tighten securely.

Servicing the clutch Assembly

NOTE: When replacing the clutch armature, the clutch hub

and clutch rotor must be replaced also. This will

allow for even wear and maximum life on clutch

parts.

Removing/Replacing the clutch Hub and Armature Assembly

1. Perform the Pressure Relief Procedure.

2. Using a 7/8” open-end wrench, loosen and remove the fluid

hose from the fitting on the back of the fluid section.

3. Hold the transducer tube with a pliers to prevent it from

rotating and turn the transducer nut counterclockwise using

a 3/4” open-end wrench. When the nut disengages the filter

housing, carefully remove the transducer from the filter

housing.

4. Locate the wire that exits the rear of the electronic pressure

control (EPC) housing and connects to the wire harness on the

engine. Disconnect this wire from its connector at the engine

wire harness.

5. Using a 1/2” wrench, remove the four hex screws and lock

washers that secure the clutch housing to the gear housing.

6. Using a 9/16” socket, remove the two hex screws that secure

the gear housing to the cart.

7. Slide the pump and gear housings away from the engine to

disengage them from the clutch housing.

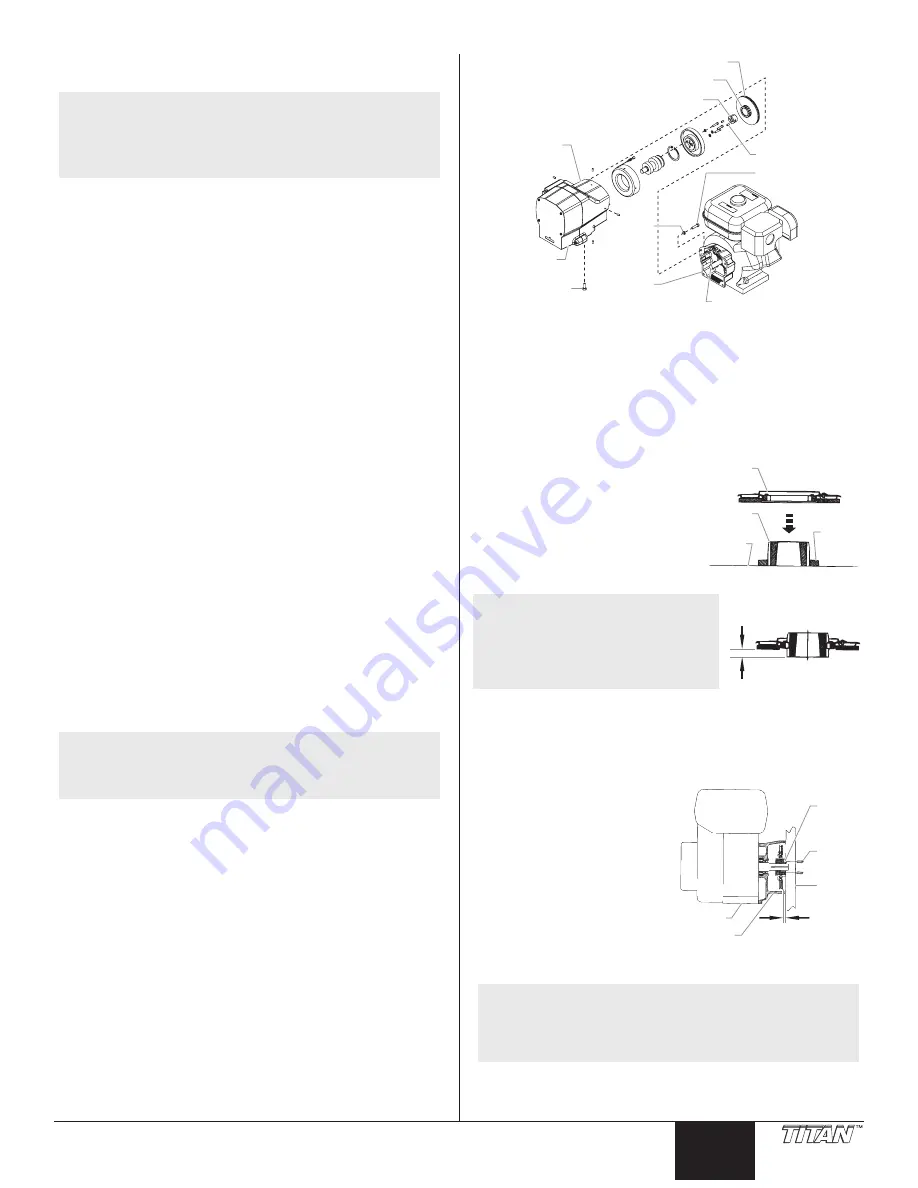

Clutch Armature

Clutch Hub

Taper Lock Bushing

Gear

Housing

Pump

Housing

Lock

Washer

Clutch

Housing

Clutch Housing

Hex Screw

Engine Shaft

Gear Housing

Hex Screw

Set Screw

8. Locate the clutch hub and armature assembly on the end

of the engine shaft. Note the two set screws as well as the

unused, threaded hole in the taper lock bushing at the center

of the clutch hub.

9. Using an 1/8” hex wrench, remove the two set screws from the

taper lock bushing

10. Thread one of the set screws into the unused, threaded hole

on the taper lock bushing. As the screw tightens, the bushing

will loosen. Once the bushing has loosened enough, slide the

clutch hub and armature assembly off the engine shaft.

Clutch

Hub

Flat

Surface

Set-Up

Tool

Clutch

Armature

11. Before replacing the clutch

hub and armature assembly

the proper “set back” must be

created. Using the Titan hub

set-up tool (P/N 0509925),

create a “set back” of 0.20”

between the friction surface

of the clutch armature and the

forward face of the clutch hub.

NOTE: A new clutch hub and

armature assembly will come

pre-assembled, but the “set

back” will not be correct. The

“set back” must still be created

using the hub set-up tool.

0.20"

12. Line up the three holes in the taper lock bushing with the

three holes in the clutch hub and insert the bushing into the

center of the clutch hub.

13. Line up the key on the taper lock bushing with the keyway on

the engine shaft and slide the assembly onto the shaft with

the holes facing out.

Clutch

Housing

0.20"

Engine

Set

Screw

Straight

Edge

Taper

Lock

Bushing

14. Apply blue Loctite to the

two set screws and insert the

screws into the taper lock

bushing. Tighten the set

screws only two turns at this

time.

15. Line up the forward face of

the clutch hub with the front

face of the clutch housing.

Using an 1/8” hex wrench,

alternately tighten the set

screws into the taper lock

bushing. Torque to 65–75 in-lbs.

NOTE: To ensure the clutch hub and the clutch housing are

aligned, hold a straight edge across the face of the

clutch housing and then hold the clutch hub against

the back of the straight edge while tightening the

two set screws into the taper lock bushing.

16. Make sure the friction surface of the clutch armature is clean

and free from oil or grease.