Replacing the Gears

1. Unplug the unit.

2. Loosen and remove the four motor shroud screws.

Remove the motor shroud.

3. Release the baffle tape on the side of the baffle assembly

and slip the baffle assembly off of the motor. Remove the

four baffle spacers.

4. Slide the electronic cover off of the electronic control

assembly on the motor.

5. Loosen and remove the four heat sink assembly mounting

screws. Pull back the heat sink assembly to access and

disconnect the two wires coming from the motor.

6. At the electronic control assembly:

a. Disconnect the white wire coming from the power cord

and the white wire coming from the ON/OFF switch.

b. Disconnect the three wires coming from the

potentiometer and the phone jack-style connector

coming from the transducer.

c. Disconnect the seven wires coming from the indicator

lights assembly.

7. Loosen and remove the four motor mounting screws.

8. Pull the motor out of the gear box housing.

9. Inspect the rotor gear on the end of the motor for damage

or excessive wear. If this gear is completely worn out,

replace the motor.

10. Remove and inspect the 2nd stage gear assembly for

damage or excessive wear. Replace, if necessary.

11. Remove and inspect the crankshaft/gear assembly for

damage or excessive wear. If damaged or worn, replace

the crankshaft/gear assembly.

12. Install the motor into the gear box housing. Make sure the

housing gasket is positioned properly and the thrust

washer is in place.

13. Secure the motor with the four motor mounting screws.

14. Reconnect the wires to the electronic control assembly

(refer to the electrical schematic in the Parts List section

of this manual).

15. Connect the two motor wires to the heat sink assembly.

16. Position the electronic cover over the electronic control

assembly.

17. Position the heat sink assembly on the gear box housing

and secure in position with the four heat sink assembly

mounting screws

18. Slip the baffle assembly around the motor. Secure the

baffle assembly with the baffle tape. Slip the four baffle

spacers into position between the rear bell of the motor

and the baffle assembly.

19. Slide the motor shroud over the motor. Make sure the

housing gasket is positioned properly.

20. Secure the motor shroud with the four motor shroud

screws.

NOTE: Clean and refill the gear box cavity up to the rear

face of each gear with Lubriplate (P/N 314-171).

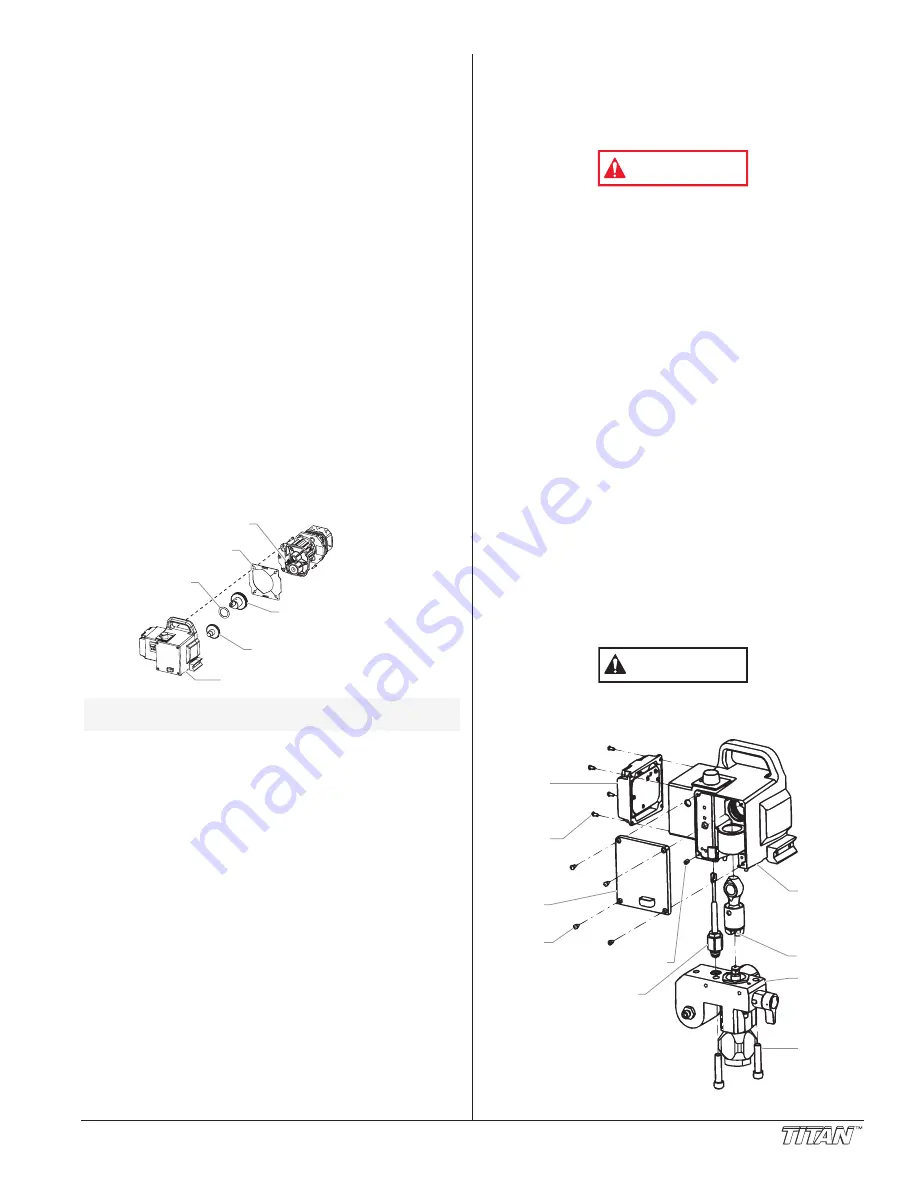

Crankshaft/Gear Assembly

2nd Stage Gear Assembly

Gear Box Housing

Housing Gasket

Rotor Gear

Thrust Washer

Replacing the Transducer

1. Loosen and remove the four front cover screws. Remove

the front cover.

2. Stop the sprayer at the bottom of its stroke so that the

piston is in its lowest position. Turn off and unplug the

sprayer.

Before proceeding, follow the Pressure Relief Procedure

outlined previously in this manual. Additionally, follow all

other warnings to reduce the risk of an injection injury,

injury from moving parts or electric shock. Always unplug

the sprayer before servicing!

3. Tilt the pump back for easy access to the fluid section.

4. Using a 3/8” hex wrench, loosen and remove the two

pump block mounting screws.

5. Pull the pump block down approximately 1/2” from the

gear box housing to clear the transducer.

6. Slide the pump block and piston rod forward until the

piston rod is out of the T-slot on the slider assembly.

7. Loosen and remove the four heat sink assembly mounting

screws.

8. Pull back the heat sink assembly for access to the

transducer wire plug-in.

9. Follow the wire from the transducer to the heat sink

assembly and unplug the transducer wire from the heat

sink assembly.

10. Using an 1/8” hex wrench, loosen and remove the set

screw from the bottom of the gear box housing.

11. Slide the transducer assembly out of the bottom of the

gear box housing.

12. Install the new transducer assembly into the gear box

housing.

13. Thread the set screw into the gear box housing and

tighten securely.

14. Plug the transducer wire into the heat sink assembly

where the old transducer wire was located.

15. Reassemble the pump by reversing steps 1–8.

Make sure the transducer is aligned properly with the hole

in the pump block during reassembly. Improper alignment

may cause damage to the transducer gasket.

T-Slot

Gear Box

Housing

Pump

Block

Pump

Block

Mounting

Screw

Front

Cover

Heat Sink

Assembly

Mounting

Screw

Heat Sink

Assembly

Front

Cover

Screw

Set Screw

Transducer

Assembly

CAUTION

WARNING

© Titan Tool Inc. All rights reserved.

9