8

• NEVER store a spare LP cylinder under or near

the appliance or in an enclosed area.

• Never fill a cylinder beyond 80% full.

• An over filled or improperly stored cylinder is a

hazard due to possible gas release from the

safety relief valve. This could cause an intense

fire with risk of property damage, serious injury or

death.

• If you see, smell or hear gas escaping,

immediately get away from the LP

cylinder/appliance and call your fire department.

DANGER

USE AND CARE

LP Cylinder Removal, Transport and Storage

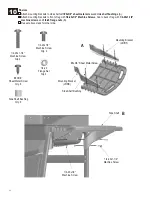

•Turn OFF all control knobs and LP cylinder valve. Turn coupling

nut counterclockwise by hand only - do not use tools to

disconnect. Loosen cylinder screw beneath bottom shelf or

and out of cart. Install safety cap onto LP cylinder valve.

Always use cap and strap supplied with valve.

Failure to use safety cap as directed may result in serious

personal injury and/or property damage.

•A disconnected LP cylinder in

storage or being transported

must have a safety cap installed (as shown).

Do not store an LP cylinder in enclosed spaces

such as a carport, garage, porch, covered

patio or other building. Never leave an LP cylinder

inside a vehicle which may become overheated

by the sun.

•Do not store an LP cylinder in an area where children play.

OPD Hand Wheel

LP (Liquefied Petroleum Gas)

•

LP gas is nontoxic, odorless and colorless when produced.

For

Your Safety

, LP gas has been given an odor (similar to rotten

cabbage) so that it can be smelled.

•

LP gas is highly flammable and may ignite unexpectedly when

mixed with air.

LP Cylinder Filling

•

Use only licensed and experienced dealers.

•

LP dealer

must purge new cylinder

before filling.

•

Dealer should

NEVER

fill LP cylinder more than 80% of LP

cylinder volume. Volume of propane in cylinder will vary by

temperature.

•

A frosty regulator indicates gas overfill. Immediately close LP

cylinder valve and call local LP gas dealer for assistance.

•Do not release liquid propane (LP) gas into the atmosphere.

This is a hazardous practice.

•To remove gas from LP cylinder, contact an LP dealer or call a

local fire department for assistance. Check the telephone

directory under “Gas Companies” for nearest certified LP

dealers.

LP Cylinder Valve

Retainer Strap

Safety

Cap

LP Cylinder

•The LP cylinder used with your grill must meet the

following requirements:

•

Use LP cylinders only with these required measurements: 12"

(30.5cm) (diameter) x 18" (45.7 cm) (tall) with 20 lb. (9 kg.)

capacity maximum.

•LP cylinders must be constructed and marked in accordance

with specifications for LP cylinders of the U.S. Department of

Transportation (DOT) or for Canada, CAN/CSA-B339,

cylinders, spheres and tubes for transportation of dangerous

goods. Transport Canada (TC). See LP cylinder collar for

marking.

•

LP cylinder valve must have:

•Type 1 outlet compatible with

regulator or grill.

•Safety relief valve.

•UL listed Overfill Protection

Device (OPD). This OPD safety

feature is identified by a unique triangular hand wheel.

Use

only LP cylinders equipped with this type of valve.

•LP cylinder must be arranged for vapor withdrawal and include

collar to protect LP cylinder valve. Always keep LP cylinders in

upright position during use, transit or storage.

LP cylinder in upright position for vapor withdrawal

disconnect other retention means, then lift PL cylinder up and

Summary of Contents for Thermos C-21G0 461611513

Page 29: ...NOTES 29 ...

Page 30: ...NOTES 30 ...