All installations and services must be performed by qualified service personnel.

11

3.

The sequence of operation of the furnace.

4.

The correct operation and maintenance of the appliance as outlined in the users information

manual.

5.

That failure to maintain and operate this furnace in accordance with these instructions could

result in hazardous conditions, bodily injury, property damage and may void the limited

warranty on the furnace.

6.

Review with and encourage the user to read the label reproductions and all warnings and

instructions outlined in this Manual.

Recommend that the user have a qualified heating contractor inspect the furnace at the start of

each heating season. Inform the user of the frequency of inspection required for each item in

Section III of the User’s Manual

III. USERS INFORMATION SECTION

A. COMBUSTION AIR SUPPLY:

The burner requires a generous amount of clean combustion

air to operate safely. Lack of adequate combustion air can result in erratic operation of the burner,

noisy combustion, or fuel odors in the air. Never block the furnace from the supply of combustion

air. If there is an exhaust fan, dryer or return air grill in the furnace room, there should be

increased concern and additional efforts may be required to provide adequate combustion oil to

the furnace at all times.

B. OIL SUPPLY:

Do not allow the fuel tank to run completely empty. During the summer, keep

the tank full to prevent condensation of moisture on the inside surface of the tank. If the fuel tank

runs completely dry, it may be necessary to purge the lines of trapped air. Contact a qualified

technician to bleed the lines and restart the burner. Turn the oil supply valve off if the burner is

shut down for an extended period of time.

C. INSPECTION AREAS

VESTIBULE:

The furnace vestibule area or burner compartment should be inspected by

removing the front door of the furnace and looking for signs of excessive heat such as

discoloration of components materials damage, from rust or corrosion, soot or carbon build-up.

EXTERIOR OF FURNACE:

The furnace exterior should be inspected for signs of excessive

heat such as discoloration of materials and damage from rust or corrosion.

FLUE PIPE, VENT PIPE OR CONNECTOR:

The furnace vent pipe should be inspected for

signs of rust, corrosion pitting or holes in pipe, and leakage around seams in pipe, indicated by

soot or condensate streaks.

CHIMNEY OR VENTING SYSTEM:

The furnace venting system should be inspected for

signs of rust, corrosion pitting or holes, and signs of condensation or moisture leakage from the

venting system.

If any of the above symptoms are evident, call a qualified heating contractor for assistance.

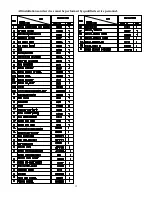

Summary of Contents for OL20FA151T60 Series

Page 2: ......

Page 5: ...All installations and services must be performed by qualified service personnel iii...

Page 19: ...All installations and services must be performed by qualified service personnel 13...

Page 21: ...All installations and services must be performed by qualified service personnel 15...

Page 23: ...All installations and services must be performed by qualified service personnel 17...