6

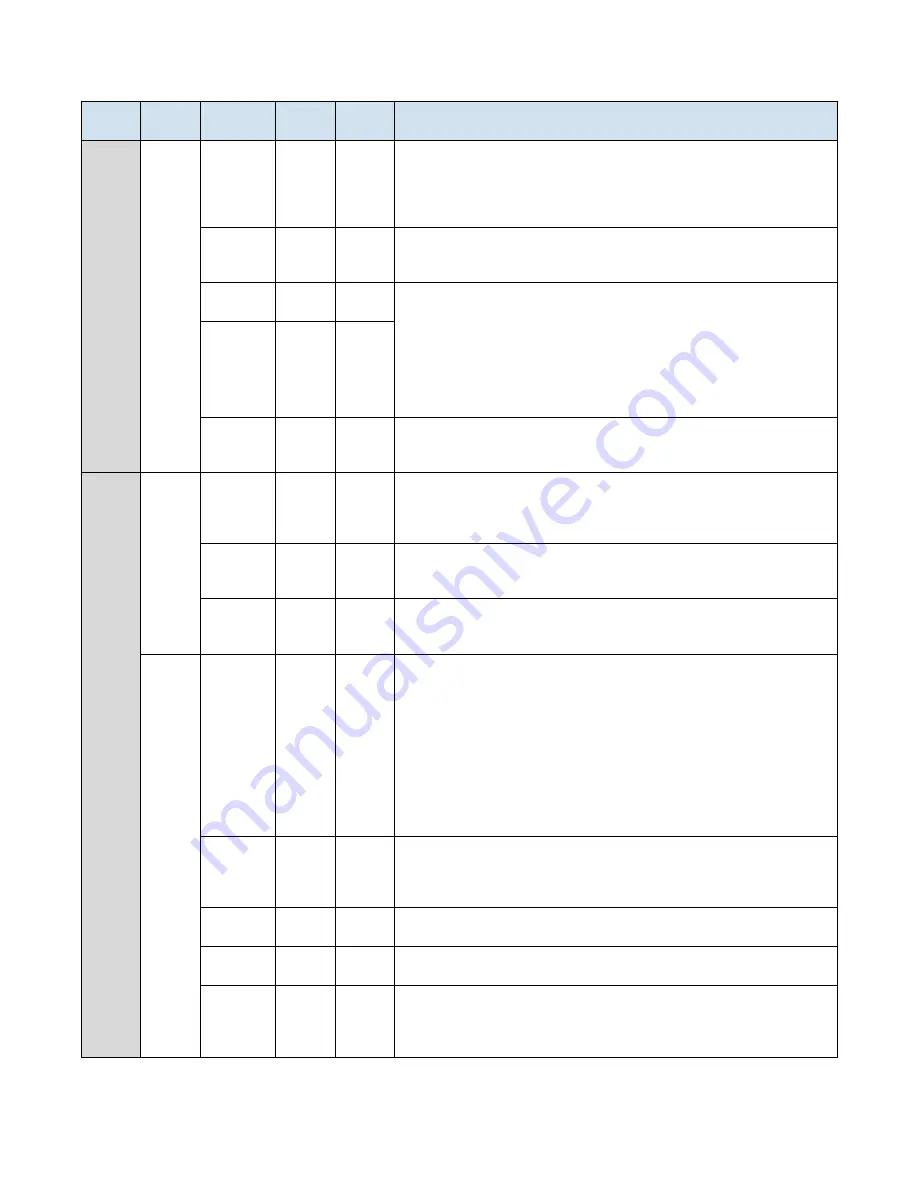

Table 1 - User Parameters (continued)

Category Screen

Number

Parameter

Default

Value

Range

Description

TCU

Setup

3/6

PV Source

To Proc

To Proc

From

Proc

To/From

Average

Allows the user to select which RTD temperature sensor is used for temperature

regulation. The selected signal is used by the control loop where it will attempt to

reach setpoint.

PV

Smoothing

5 sec

0 to 720 Used to smooth the RTD temperature probe signal. Normally, this should remain

in the 0-10 sec range, but can be increased if process fluid is not an equal

temperature throughout.

Low Pres

Count

3

1 to 25

Both of these parameters work hand-in-hand to define the TCU’s reaction to

multiple process fluid low-pressure events while the TCU is in operation. By

default, the TCU will tolerate up to 3 process fluid low-pressure events every 15

minutes; the TCU temporarily shuts down during the low-pressure event, and

automatically restart when the pressure returns. Because excessive, frequent

starting/stopping of the TCU can cause motor/pump damage, the purpose of

these parameters is to protect the TCU if operating in an environment with

unstable fluid pressure.

Low Pres

Time

15 min

1 to 999

Units

°F

°F or °C

Used to select the desired temperature unit of measure. After changing, the

controller will automatically reboot. Note that this parameter is NOT automatically

set to default if the user executes a “Load Defaults” to reset to default parameters.

Venting

4/6

Valve Vent

30 sec

5 to 180 Upon cold startup, the TCU will flush the process loop with fresh fluid to remove

air. The pump will not run during this time. Once finished, it will start the pump

and continue to flush with the pump’s assistance. No loop-temperature regulation

occurs in this state. Increase this value if you have an excessively long fluid loop.

Valve/Pmp

Vent

30 sec

5 to 180 Upon cold startup, and after the “Valve Vent” parameter’s time has expired, the

TCU will start the pump to assist in deaeration. No loop-temperature regulation

occurs in this state. Increase this value if you have an excessively long fluid loop.

Vent Bypass 120°F

32 to 260 If the process loop is above this temperature, the “Valve Vent” and “Valve/Pmp

Vent” will not occur. This makes the TCU restarts quickly, while still deaerating if

the machine starts from a cold state.

Control

Loop

5/6

System Size ---

Small

Medium

Large

This setting quickly selects factory-suggested parameters below for P-Band, I-

Gain, D-Gain, and Deadband. Select the setting that best describes your system.

“Large” is for a slow setting for systems with more than 80 gallons of fluid volume

and more than 5,600 lbs of steel mold mass. This setting has a proportional band

of 3ºF to allow a slower response. “Normal” is the factory default tuning setting

and covers the majority of applications with 10 to 80 gallons of fluid volume and

700 to 5,600 lbs of steel mold mass. This setting has a proportional band of 7ºF.

“Small” is for fast setting for systems with less than 10 gallons of fluid volume and

less than 700 lbs of steel mold mass. This setting has a proportional band of 15ºF

to allow a fast response. Alternatively, you can also directly edit the PID settings as

described below.

P-Band

10 Δ°F

0.2 to

999.7

Proportional Band for PID temperature control. A smaller number will promote a

more aggressive proportional response. At the default 10 Δ⁰F, this means that the

proportional response will be at 100% when the temperature is 10 Δ⁰F from

setpoint.

I-Gain

50

0 to 999 Integral Gain for PID temperature control. A smaller number will promote a more

aggressive integral response. Zero will disable all integral responses.

D-Gain

10

0 to 999 Derivative Gain for PID temperature control. A larger number will promote a more

aggressive derivative response. Zero will disable all derivative responses.

Deadband

0.5 Δ°F

0 to 99.9 Defines a region of process temperature deviation that will have no effect in PID

control loop. By having a deadband, wear-and-tear on the TCU is minimized

because it does not have to try as hard to maintain the process temperature

perfectly to setpoint.

Summary of Contents for Aquatherm RQE

Page 1: ......

Page 2: ......

Page 4: ...Page Intentionally Blank...

Page 20: ...16 Notes...

Page 21: ...17 Notes...

Page 22: ...18 Notes...

Page 23: ......