OPERATING INSTRUCTIONS

BEFORE USE

All units are wiped clean with solvents at the factory to remove any visible signs of dirt, oil or grease

remaining from the manufacturing process.

Open Tops & Broilers

The Top grates should be removed and washed before use. With these removed it will be possible to remove

plastic ties holding the burners in place for shipment.

Griddle

New griddles should be seasoned as follows:

1.

Clean the griddle surface thoroughly with hot soapy water to remove the protective oil coating wiped

on at the factory.

2.

Rinse with a mixture of ¼ cup vinegar to one-quart water.

3.

Spread unsalted shortening or liquid frying compound evenly over the entire griddle surface.

4.

Turn all griddle burners to medium or thermostats to 350 degrees and wait until the shortening begins

to smoke, and then turn the burners off.

5.

Rub the now melted shortening into the griddle surface with a cloth covering the entire surface.

6.

Let the griddle cool, and then repeat steps 3, 4, & 5.

7.

When the griddle is cool after the second seasoning, wipe it once again with a thin film of shortening

or cooking oil.

OPERATING SUGGESTIONS

Open Tops

Open top burners are quickly lighted and require no preheating time. Light only as many burners as needed.

Broiler

Allow the grates to thoroughly heat before using. During slow periods heat only the portion required.

Griddle

Heat the griddle thoroughly before using. During slow periods the top can be kept warm with the burners

turned partially down, or heat only the portion of the griddle required.

6

Summary of Contents for TC36-6

Page 10: ...9 HOT PLATE Counter Series ...

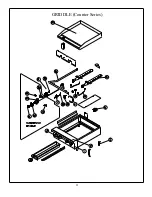

Page 12: ...GRIDDLE Counter Series 11 ...

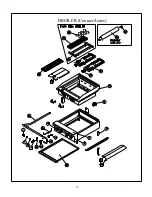

Page 14: ...BROILER Counter Series 13 ...