INSTALLATION AND SAFETY GUIDELINES

GAS CONNECTION

The gas supply (service) line must be at least the same size or larger than the inlet line of the appliance.

CHEFTECH counter equipment is supplied with a ¾” NPT Schedule 40 inlet. Sealant on all pipe joints must

be resistive to LP gas.

MANUAL SHUT-OFF VALVE

A manual shut-off valve must be installed in the gas service line ahead of the appliance and regulator in the

gas stream and in a position where it can be reached quickly in the event of an emergency. The manual shut-

off valve is supplied by the installer.

PRESSURE REGULATOR

All commercial cooking equipment must have a pressure regulator on the incoming service line for safe and

efficient operation, since pressure may fluctuate on local demand. A regulator is supplied with the appliance.

Failure to install a pressure regulator will void the equipment warranty.

The regulators are adjusted at

the factory, 5.0” WC for natural gas, and 10.0” WC for propane gas. Ensure the supply pressure is within the

following range: Natural Gas 6.0” WC to 13.0” WC / Propane Gas 11.0”WC to 13.0” WC.

Any adjustments to the regulators must be made

only

by qualified service personnel with proper test

equipment.

RIGID CONNECTIONS

Double check any installer supplied gas pipes visually and blow them out with compressed air to clear any

dirt particles, threading chips, or any other foreign matter before installing a service line. Those particles will

clog orifices when gas pressure is applied. All connections must be sealed with a joint compound for LP gas

and tested with a soapy water solution before lighting any pilots.

FLEXIBLE COUPLINGS, CONNECTORS AND CASTERS

If the unit is to be installed with flexible coupling and or quick disconnect fittings, the installer must use a

heavy duty commercial flexible connector at least ¾” NPT (with suitable strain relief) in compliance with the

standard for connectors for movable gas appliances, ANSI Z21.69-1987 and Addenda Z2.169a-1989 (or latest

edition) or connectors for movable appliances, CAN/CGA-6.16 (or latest edition) and quick disconnect device

must comply with the standard for quick disconnect devices for use with gas fuel,

ANSI Z21.41-1989 (or latest edition) or quick disconnect devices for use with gas fuel, CAN1-69 (or latest

edition). Adequate means must be provided to limit the movement of the appliance. Domestic connectors are

not suitable.

When the appliance is supplied with casters and is connected to the supply piping by means of a connector for

movable appliances, and if disconnecting the restraint is necessary, this restraint must be reconnected after the

appliance is returned to its original installation position. The strain relief is a cable attached to the rear of the

appliance.

4

Summary of Contents for TC36-6

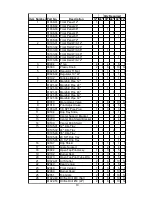

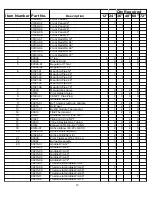

Page 10: ...9 HOT PLATE Counter Series ...

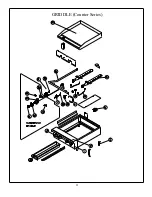

Page 12: ...GRIDDLE Counter Series 11 ...

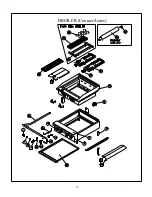

Page 14: ...BROILER Counter Series 13 ...