Nozzle Maintenance

1. If nozzle clogs, remove and disassemble the nozzle assembly.

2. Clean the openings of any obstructions and reassemble.

Cleaning

1. Fill the tank with cool, clean tap water. Replace the cap and tighten

securely. (

Note: Never use hot water for cleaning.

)

2. Agitate the tank to rinse the chemical from the tank walls.

3. Remove the cap and empty the contents into gravel or bare soil.

4. Refill the tank with clean tap water. Replace the cap and tighten securely.

5. Pressurize the tank as described in the

Pressurizing and Spraying

section.

6. Direct the nozzle away from you and activate the shut-off for at least 30 seconds to clean the

pressure cylinder, hose and shut-off.

7. Remove the cap and empty the contents into gravel or bare soil.

8. Repeat steps 4 - 7 until thoroughly cleaned. Remove nozzle when flushing pump system. Clean nozzle

before replacing.

Sprayer Storage

1. Never store sprayer with pressure in reservoir or liquid in any part of sprayer.

2. Sprayer tank should be hung upside down, with the cap removed, to dry completely.

3. Do not store or leave any solution in the tank after use.

4. Store in a warm, dry location out of direct sunlight.

5. Keep the sprayer and all chemicals out of the reach of children.

Tank Maintenance

1. After each use, rinse the tank with cool, clean water.

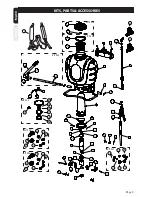

2. Check the check valve

(See Figure G

)

and filter basket gasket

(See

Figure H

)

.

Make sure they do not show signs of wear and are

operating properly. Replace them as required.

3. Clean any dirt or debris from the filter basket.

4. Periodically check the straps for fraying.

Replace them as required.

Shut-off Maintenance (Smith Pro II)

Always depressurize sprayer before maintenance

by activating shut-off and spraying contents out.

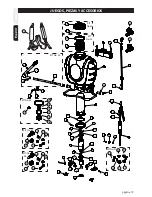

1. Unscrew the handle from the shut-off assembly.

2. Remove the filter from the shut-off assembly.

3. Clean any debris from inside the handle, shut-off

assembly, or the filter by rinsing with cool, clean water.

4. Reassemble the components as shown and

tighten all connections securely.

MAINTENANCE

Figure G

Figure H

Page 4

3. To maintain pressure while spraying, operate pump handle every 8 sec.

or as needed.

4. For continuous spraying, squeeze lever and rotate lock.

(See Figure F)

5. Unlock if needed and release shut-off lever to stop spraying.

Figure F

A. Handle

B. Filter

C. Shut-off Assembly

A

B

C

LEVER

A

C

B