©Copyright Task Force Tips, Inc. 2006-2018

LIX-730 January 8, 2018 Rev08

6

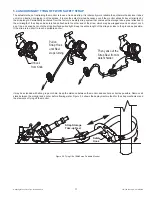

2.5.1 ELEVATION HOLDING MECHANISM

The elevation pivot has a mechanism to support the weight of a nozzle. It is factory set to support the weight of nozzles likely to be

used. It may be adjusted (see fi gure 2.5). The mechanism releases when raising the nozzle so upwards drag from the mechanism

is not felt. Avoid the use of long stream straighteners or heavy nozzles which may overcome the holding torque of the elevation

mechanism.

3.0 FLOWS AND PRESSURES

The BlitzForce Portable Monitor is designed for maximum fl ows of 500 GPM (2000 LPM) and a maximum pressure of 175 PSI (12

BAR). Do not exceed these limits.

WARNING

An inadequate supply of pressure and/or fl ow will cause an ineff ective stream and can result in

injury, death or loss of property.

3.1 AUTOMATIC, FIXED, AND SELECTABLE FLOW NOZZLES

A variety of water or foam nozzles may be used with the BlitzForce Portable Monitor.

Automatic nozzles maintain a constant pressure by adjusting their opening to match the available fl ow. Consult the nozzle manufacturer

for maximum fl ow and pressure ratings. In all cases do not exceed 500 GPM (2000 LPM) and/or 175 PSI (12 BAR).

3.2 STACKED TIPS OR SMOOTHBORE NOZZLES

NOZZLE

DIAMETER

NOZZLE INLET PRESSURE

50 PSI

80 PSI

100 PSI

150 PSI

175 PSI

FLOW

(GPM)

REACTION

(LBS)

FLOW

(GPM)

REACTION

(LBS)

FLOW

(GPM)

REACTION

(LBS)

FLOW

(GPM)

REACTION

(LBS)

FLOW

(GPM)

REACTION

(LBS)

1.0 INCH

210

80

266

126

297

157

364

236

390

275

1-1/4 INCH

328

120

415

196

464

245

—

—

—

—

1-1/2 INCH

473

177

—

—

—

—

—

—

—

—

NOZZLE

DIAMETER

NOZZLE INLET PRESSURE

4 BAR

6 BAR

8 BAR

10 BAR

12 BAR

FLOW

(L/min)

REACTION

(KG)

FLOW

(L/min)

REACTION

(KG)

FLOW

(L/min)

REACTION

(KG)

FLOW

(L/min)

REACTION

(KG)

FLOW

(L/min)

REACTION

(KG)

25 MM

830

40

1000

60

1200

80

1300

100

1400

120

32 MM

1300

70

1700

100

1900

130

—

—

—

—

38 MM

1900

90

—

—

—

—

—

—

—

—

FLOW EXCEEDS RATING OF BlitzForce PORTABLE MONITOR

3.3 STREAM STRAIGHTENERS

Stream quality, especially with smooth bore nozzles, is generally improved with the use of a stream straightener. A stream straightener

is integrated into the exit of the monitor.

3.4 USE WITH FOAM

The monitor may be used with various foam nozzles and foam solutions. Refer to fi re service training for the proper use of foam.

3.5 USE WITH SALT WATER

Use with salt water is permissible provided the monitor is thoroughly cleaned with fresh water after each use. The service life of the

monitor may be shortened due to the eff ects of corrosion and is not covered under warranty.