©Copyright Task Force Tips, Inc. 2006-2018

LIX-730 January 8, 2018 Rev08

18

9.0 XXL-B Storage Bracket INSTALLATION INSTRUCTIONS

Tools Required: Electric Drill

Drill Bits see instructions for correct size

#3 Phillips Screw Driver

7/16 or adjustable wrench

5/32 allen wrench

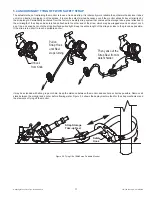

The BlitzForce Portable Monitor storage bracket must be securely mounted to

a surface capable of supporting the weight of the Monitor including any shock

loads that may result from rough roads. The storage bracket may be mounted on

a vertical surface, or a horizontal surface with the nozzle end pointing down or

sideways as shown below. It is the responsibility of the installer to determine if the

installation is capable of these loads.

WARNING

Do not use the BlitzForce Portable Monitor Storage Bracket as a mount when fl owing water.

Nozzle reaction will cause monitor instability. The BlitzForce Portable Monitor Storage Bracket

is designed to store the BlitzForce Portable Monitor.

The BlitzForce Portable Monitor Storage Bracket comes with 1/4-20 Stainless Steel Self tapping screws. If the material beneath

the Storage Bracket is thick and substantial enough, the self-tapping screws may be screwed directly into the mounting surface. If

the backside of the mounting surface is accessible, clearance holes may be drilled, and the nuts and washers may be used on the

backside. It is the responsibility of the installer to determine if the mounting surface is satisfactory.

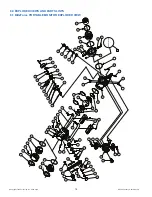

9.1 FOR BLIND MOUNTING:

Lay the bracket in the area where the monitor will be mounted. The end of the bracket with the bent & welded sides goes toward the

monitor outlet. Make sure there is enough clearance to get the monitor in and out of the bracket and that it does not interfere with

other equipment on the truck.

Make sure the material beneath the bracket is substantial and thick enough to hold self-tapping screws as well as the weight of

the monitor. Make sure the area on the other side of the mounting surface is clear, you don’t want to drill into a bundle of wires.

We recommend a minimum thickness of 3/32” (.093” - 2.4 mm) in aluminum and 5/64 (.078”-2mm) in steel. Using the bracket as

a pattern, drill through one hole into the mounting surface and install one screw. See the chart on the next page to determine the

correct hole size. While the fi rst screw holds the bracket from moving, drill the remaining holes and screw in the remaining screws.

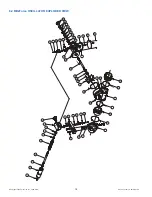

9.2 FOR MOUNTING WHERE THE BACK OF THE MOUNTING SURFACE IS ACCESSIBLE:

Lay the bracket in the area where the monitor will be mounted. The end of the bracket with the bent & welded sides goes toward the

monitor outlet. Make sure there is enough clearance to get the monitor in and out of the bracket and that it does not interfere with

other equipment on the truck.

Make sure the material beneath the bracket is substantial enough to hold the weight of the monitor. Make sure the area on the other

side of the mounting surface is clear, you don’t want to run a drill into a bundle of wires. Using the bracket as a pattern, drill one ¼”

(.250” - 6.4 mm) diameter hole through the bracket and bolt the bracket to the mounting surface from the backside. (Put the washers

on the side with the nuts). While the fi rst screw holds the bracket from moving, drill the remaining holes and screw in the remaining

screws. Secure with washers and nuts.