Texmate, Inc. Tel. (760) 598-9899 • www.texmate.com

DL-40JANUS-DCA/DCV manual (d0114)

Page 5

When the rear Auto/Manual switch is in the Auto position, the meter can be calibrated with an automatic scale factor calculation,

by applying a low input signal (InLo), entering the desired low display reading for that signal (ZERO), then applying a high input

signal (InHi), and then entering the desired high display reading (SPAN). The meter then automatically calculates and programs in

the requisite scale factor using a true linear (y=mx + b) calculation where m = (SPAN-ZERO)/(InHi-InLo) and b = ZERO, but within

the following parameters.

1. Positive and negative signals may be applied, but the difference between the high and the low signal inputs must be at least 1000

counts or Err will be indicated.

2. Positive and Negative values for the desired reading can be entered, but the scale factor created can not exceed the Digital

Display Span capability of the meter which is 12,000 counts between –1999 to 9999.

3. The internal Signal Span is limited to 3 V DC between – 1 V DC to + 2 V DC. Any outputs from an Input Signal Conditioning

module that exceed these limits will cause the meter to indicate overrange regardless of the Digital Display Span scaled.

Note: Most input signal conditioners have provisions for analog calibration and scaling. If the meter’s digital scale factor is set to

read zero with a zero input (shorted input), and to read 1000 with a 1.000 V input, any pre-calibrated signal conditioner with an

output that does not exceed – 1 V to + 2 V, will read correctly in the meter without any further calibration.

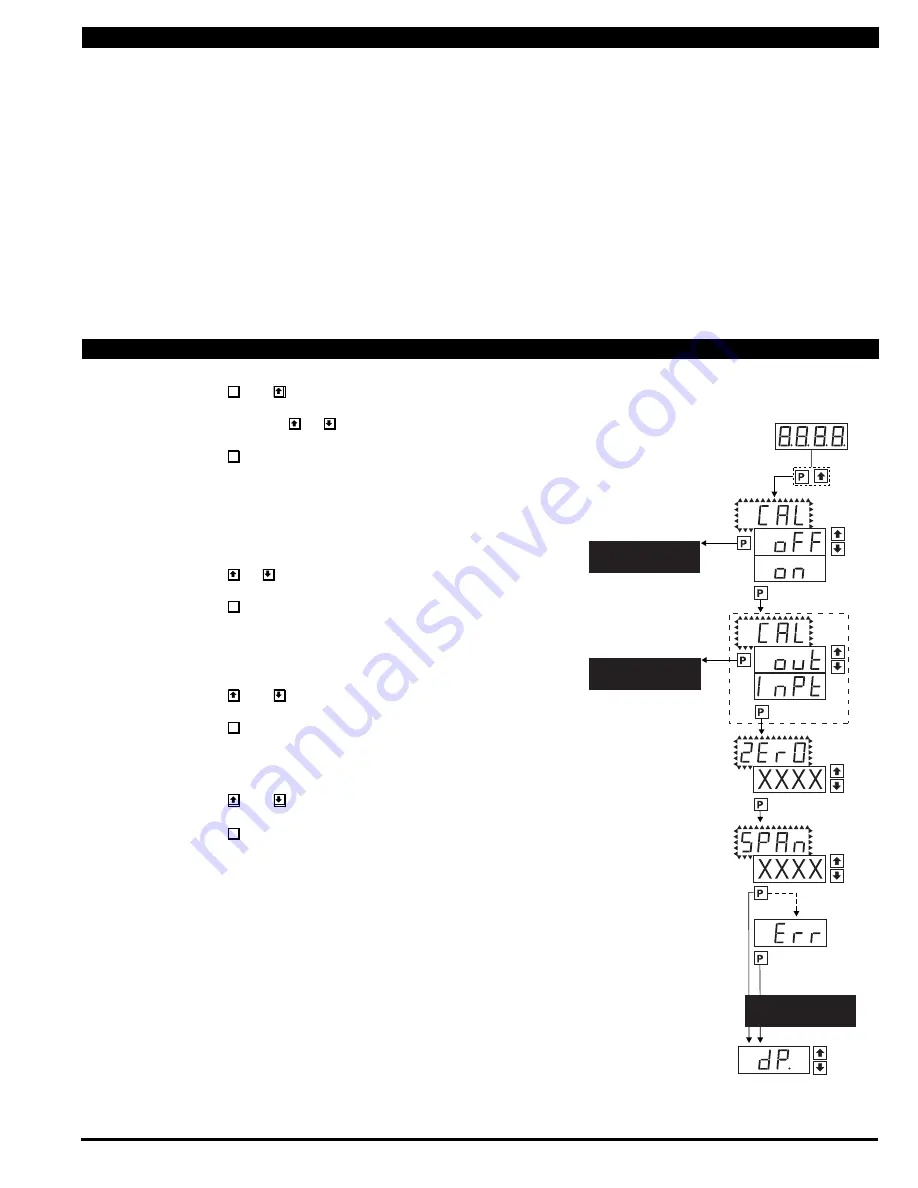

STEP A Enter the Calibration Mode

1) Press the

P

and buttons at the same time.

Display toggles between [CAL] and [oFF].

2) Press and hold the or button.

Display changes from [oFF] to [on].

3) Press the

P

button. Display toggles between [ZErO] and the

previous zero setting.

STEP B Select Between Two Point Digital Calibration of Input Signal and

Two Point Analog Output

Note: If the analog output option is not present, Step B is skipped and the

program goes directly from Step A to Step C.

1) Press the or button to select the display toggling from [CAL]

to [inPt] input calibration.

2) Press the

P

button. Display toggles between [ZErO] and the

previous zero setting.

STEP C Set the Meter’s Low Input Signal Reading on the Digital Display

1) Apply a zero or low signal to the meter.

(Positive or negative values are allowed)

2) Using the and buttons, adjust the meter display to the

desired reading for the applied low input signal.

3) Press the

P

button. Display toggles between [SPAn] and the

previous span setting.

STEP D Set the Meter’s High Input Signal Reading on the Digital Display

1) Apply a high input signal to the meter.

2) Using the and buttons, adjust the digital display to the

desired reading for the applied high input signal.

3) Press the

P

button.

The Digital Calibration Procedure Mode is Now Complete.

If the digital calibration was successfully completed, the menu

branches to the DISPLAY FUNCTION CONFIGURATION MODE,

(see page 7) and the display flashes [dP] and the previous setting.

ERROR Indicates Unsuccessful Calibration

If the calibration was unsuccessful, the display indicates [Err],

the new calibration settings just entered will not take effect and

the previously stored setting will remain.

The three most likely causes of an error during calibration are:

1) The full scale and zero signals were too similar. The full scale

signal must be at least 1000 counts greater than the zero or

low input signal (positive and negative values are allowed).

2) The scaling requirement exceeded the capability of the meter

(–1999 to 9999).

3) No input signal present, or incorrect connections.

Auto Calibration Mode

Auto Calibration Procedure

MAIN MENU

Operational Display

Sub-menu

MODE

STEP A

Calibration

Mode

STEP B

Calibration

Mode

DECIMAL POINT AND

BRIGHTNESS SELECTION

See Page 6

STEP C

Zero

STEP D

Span

DECIMAL POINT AND

BRIGHTNESS SELECTION

See Page 6

Decimal Point

(dp)

Err. Any new setting

canceled and previous

settings are retained

TWO POINT ANALOG

OUTPUT CALIBRATION

SEE PAGE 6