Page 10

CL-B101D40PS Manual (d0096)

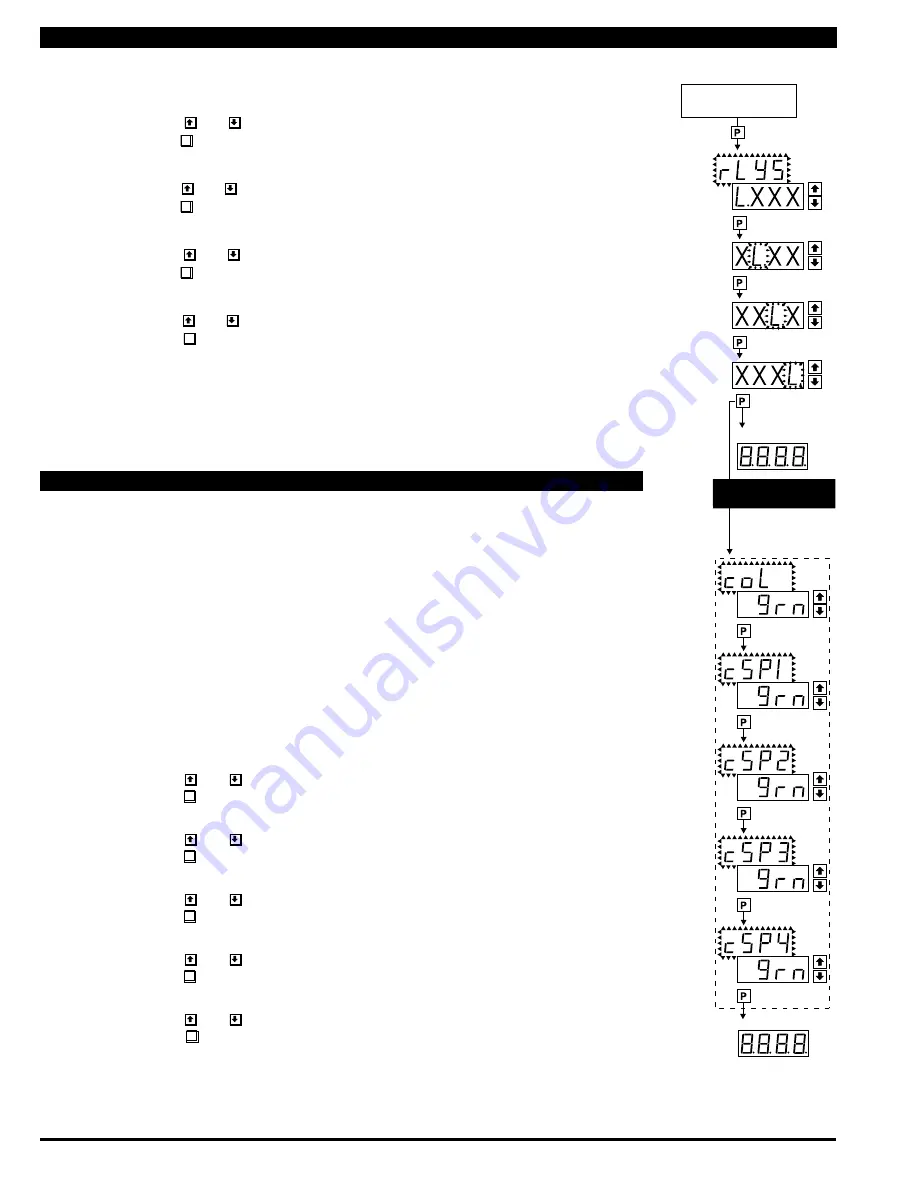

STEP M

STEP N

STEP O

STEP P

STEP Q

STEP R

STEP S

STEP T

STEP U

[orAn]

[rEd]

NOTE: Will only

appear if a tricolor

display is installed

[orAn]

[rEd]

[orAn]

[rEd]

[orAn]

[rEd]

[orAn]

[rEd]

BARGRAPH COLOR

PROGRAMMING MODE

Operational Display

Operational Display

From From Step L of

Setpoint Setting and Relay

Configuration Page 8

L or h

L or h

L or h

L or h

To comply with the latest safety requirements, the tri-color bargraph is designed like a traffic light, to

display either red, orange or green, but only one color at a time. When the bar reaches a selected

color change point, the entire bar will change to the color designated for that zone. This eliminates any

ambiguity as to the signal status, especially just after transitioning to a new zone.

First

(Step Q) is to select the color to be displayed, when the bar is “below*”, whichever set point is set

to the lowest position.

Second

(Steps R, S, T, and U) is to select the color to be displayed when the bar is above each specific

set point, regardless of the order or position to which the set points are set.

However, if two or more setpoints with differently specified colors are positioned at the same set point

value, the color specified for the set point with the highest identifying number will be displayed. When

set points are set to the same value, the SP4 color overrides the SP3 color, the SP3 color overrides the

SP2 color, and the SP2 color overrides the SP1 color.

STEP Q Select Bargraph Color when the bar is BELOW* the Setpoint that is set to the lowest

position

1) Using the and buttons, select the desired bargraph color [grn], [oran] or [red]

2) Press the

P

button. Display toggles between [CSP1] and the previous color setting.

STEP R Select Bargraph Color when the bar is ABOVE* SP1 Setpoint

1) Using the and buttons, select the desired bargraph color [grn], [oran] or [red]

2) Press the

P

button. Display toggles between [CSP2] and the previous color setting.

STEP S Select Bargraph Color when the bar is ABOVE* SP2 Setpoint

1) Using the and buttons, select the desired bargraph color [grn], [oran] or [red]

2) Press the

P

button. Display toggles between [CSP3] and the previous color setting.

STEP T Select Bargraph Color when the bar is ABOVE* SP3 Setpoint

1) Using the and buttons, select the desired bargraph color [grn], [oran] or [red]

2) Press the

P

button. Display toggles between [CSP4] and the previous color setting.

STEP U Select Bargraph Color when the bar is ABOVE* SP4 Setpoint

1) Using the and buttons, select the desired bargraph color [grn], [oran] or [red]

2) Press the

P

button. The meter exits the setpoint mode and returns to the operational

display.

The Bargraph Color programming mode is now complete.

STEP M Set Relay Activation mode [rLYS] for SP1

(h) High the relay energizes when the setpoint is exceeded. (L) Low the relay energizes below

the setpoint. The setpoint is indicated from left to right SP1, SP2, SP3, SP4.

1) Using the and buttons, select (L) or (h) for the first digit, which corresponds to SP1.

2) Press the

P

button. The SP2 Relay Activation digit begins to flash, and its decimal point is lit.

STEP N Set High (h) or Low (L) for SP2

1) Using the and buttons, select (L) or (h) for the second digit, which corresponds to SP2.

2) Press the

P

button. The SP3 Relay Activation digit begins to flash, and its decimal point is lit.

STEP O Set High (h) or Low (L) for SP3

1) Using the and buttons, select (L) or (h) for the third digit, which corresponds to SP3.

2)

Press the

P

button. The SP4 Relay Activation digit begins to flash, and its decimal point is lit.

STEP P Set High (h) or Low (L) for SP4

1)

Using the and buttons, select (L) or (h) for the fourth digit, which corresponds to SP4.

2) Press the

P

button.

If a mono-color red or green display is installed then the Setpoint Relay Programming Mode is now complete and the

meter returns to the operational display.

If a tricolor bargraph display is installed then the Bargraph Color Programming Mode will be entered and

display toggles between [CoL] and the previous setting. Color selection menu will be displayed.

Setpoint Setting and Relay Configuration Mode Continued

Bargraph Color Programming Mode