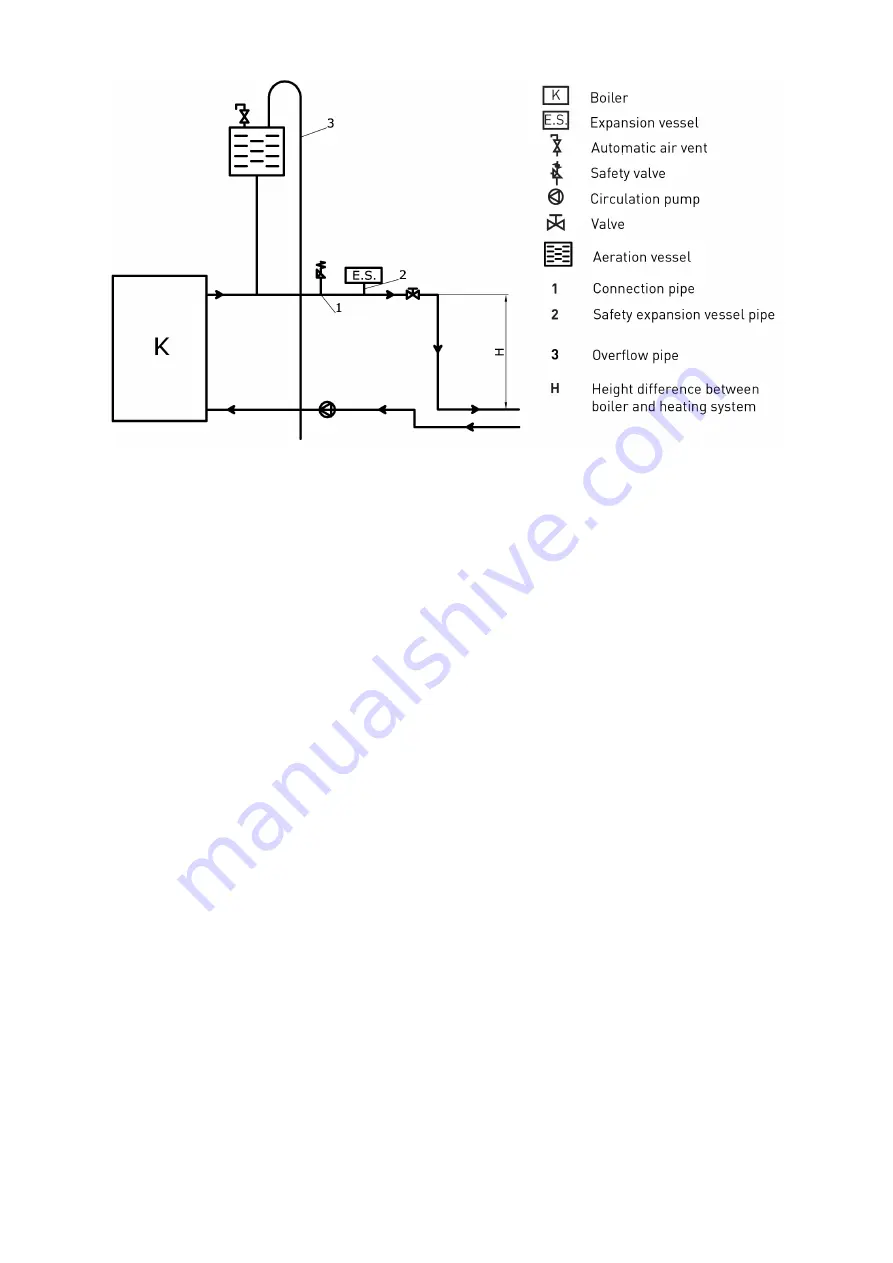

Aeration vessel to be fitted at highest point of the system at top of boiler outlet. This should include

an overflow system with valve to discharge air from the boiler to prevent overheating.

A float operated valve allows water into a cistern fitted with an overflow pipe. When the system is

filling, the valve remains open. When the system is full the valve closes.

Temperature of hot water within a storage system.

Irrespective of the type of fuel used for

heating, the temperature of the water at any point within a hot water storage system should not exceed

100 ˚C and appropriate vent pipes, temperature control devices and other safety devices should be

provided to prevent this occurring.

Safety Pressure Valve (PSV).

The safety pressure valve must always be positioned and mounted

close to the boiler. It must be easily identifiable and allow for easy access. The safety pressure valve must

be set to a nominal pressure of 2.5 bar. The valve must open and operate smoothly at 2.5 bar. Diameter

for the aperture at the seat of the valve must be at least 15mm. Connecting pipe- work to the boiler

must be as short as possible. Welds, joints or any possible blockage to this pipe-work must be prevented.

Bends in the pipe-work should be avoided if possible. Unavoidable bends should be at diameter r>3D

(D = radius of curvature) and less than

α

> 90 ˚C.

Closed expansion vessel.

The closed expansion vessel shall be fitted close to the boiler. Connecting

pipe-work should be as short as possible. Fit the expansion vessel in horizontal alignment to the pipe

to ensure equal distribution of pressure. The volume of the expansion vessel is determined by the out-

put/capacity of the boiler. A ratio of 1 kW:1 litre should be used.

The safety pressure valve and the expansion vessel should be fitted in close proximity to each other,

in the following order: expansion vessel closest to the boiler, followed by the safety pressure valve.

It is also recommended to mount a dirt remover on the RETURN line.

In the event of power failure and the boiler fails to operate correctly – any sudden increase of pressure

will be controlled first by the expansion vessel, on any further increase in pressure the safety pressure

valve will open.

6