8

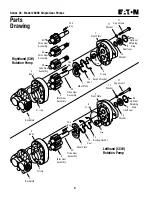

Series 26 - Model 26000 Single Gear Pumps

Inspection

Model Number

26001

26002

26003

26004

26005

26006

26007

26008

26009

26010

26011

26012

26013

Pump Disp.

6,6

8,2

9,5

10,8

13,8

16,7

19,7

22,5

24,3

25,2

27,7

29,0

30,6

cm

3

/r [in

3

/r]

[.40]

[.50]

[.58]

[.66]

[.84]

[1.02]

[1.20]

[1.37]

[1.48]

[1.54]

[1.69]

[1.77]

[1.87]

Gear Width

7,85

9,75

11,20

12,95

16,15

19,35

22,56

25,76

28,12

28,96

32,16

33,78

35,36

mm [in]

[.309]

[.384]

[.441]

[.510]

[.636]

[.762]

[.888]

[1.014]

[1.107]

[1.140]

[1.266]

[1.330]

[1.392]

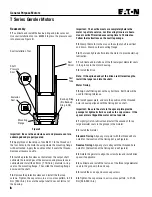

Front plate and Backplate Inspection

1

Oil groove in bushings in front plate should be in line with

dowel pin holes and 180

°

apart. The oil grooves in the

backplate bushings should be at approximately 37

°

to the

pressure side.

2

Replace the backplate or front plate if I.D. of bushings

exceed 19,2 mm [.755 in] (Bushings are not available as

separate items).

3

Bushings in front plate should be at 3,20 mm [.126 in]

above surface of front plate.

4

Check for scoring on face of backplate. Replace if wear

exceeds ,038 mm [.0015 in.].

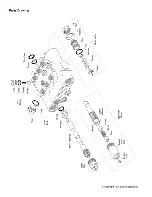

Body Inspection

1

Check body inside gear pockets for excessive scoring or

wear.

2

Replace body if I.D. of gear pockets exceeds 43,7 mm

[1.719 in].

Inspect Parts for Wear

General

1

Clean and dry all parts.

2

Remove all nicks and burrs from all parts with emery

cloth.

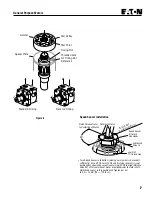

Gear Assembly Inspection

1

Check spline drive shaft for twisted or broken teeth or

check keyed drive shaft for broken or chipped keyway.

2

Inspect both the drive gear and idler gear shafts at

bushing points and seal area for rough surfaces and excessive

wear.

3

Replace gear assembly if shaft measures less than 19 mm

[ .748 in] in bushing area. (One gear assembly may be replaced

separately; shafts and gears are available as assemblies only.)

4

Inspect gear for scoring and excessive wear.

5

Replace gear assembly if gear width is below the following

dimensions. Refer to chart on this page.

6

Assure that snap rings are in grooves on either side of

drive and idler gears.

7

If edge of gear teeth are sharp, break edge with emery

cloth.

Summary of Contents for 6200D

Page 1: ...330395 Rev 01 6 02 Service Manual 6200D 330395 ...

Page 4: ...GENERAL INFORMATION 1 2 6200D 330395 8 99 ...

Page 18: ...GENERAL INFORMATION 1 16 6200D 330395 8 99 ...

Page 20: ...CHASSIS 2 2 6200D 330395 8 99 ...

Page 74: ...CHASSIS 2 56 6200D 330395 8 99 ...

Page 76: ...SWEEPING 3 2 6200D 330395 8 99 ...

Page 138: ...SWEEPING 3 64 6200D 330395 6 02 ...

Page 140: ...ELECTRICAL 4 2 6200D 330395 8 99 ...

Page 176: ...ELECTRICAL 6200D 330395 6 02 4 38 ELECTRICAL SCHEMATIC 353188 D ...

Page 177: ...ELECTRICAL 4 39 6200D 330395 6 02 WIRE HARNESSES GROUP 352986 353189 D ...

Page 178: ...ELECTRICAL 6200D 330395 6 02 4 40 WIRE HARNESSES GROUP 352986 353189 D ...

Page 179: ...ELECTRICAL 4 41 6200D 330395 6 02 WIRE HARNESSES GROUP 352986 353189 D ...

Page 180: ...ELECTRICAL 6200D 330395 6 02 4 42 WIRE HARNESSES GROUP 352986 353189 D ...

Page 181: ...ELECTRICAL 4 43 6200D 330395 6 02 WIRE HARNESSES GROUP 352986 353189 D ...

Page 182: ...ELECTRICAL 6200D 330395 6 02 4 44 WIRE HARNESSES GROUP 352986 353189 D ...

Page 184: ...HYDRAULICS 5 2 6200D 330395 8 99 ...

Page 212: ...HYDRAULICS 5 30 6200D 330395 8 99 HYDRAULIC SCHEMATIC PROPEL ...

Page 213: ...HYDRAULICS 5 31 6200D 330395 8 99 HYDRAULIC SCHEMATIC HOPPER LIFT ...

Page 214: ...HYDRAULICS 5 32 6200D 330395 6 02 OUT IN B A B A 2 3 4 5 6 1 HYDRAULIC HOSE DIAGRAM PROPEL ...

Page 215: ...HYDRAULICS 5 33 6200D 330395 6 02 HYDRAULIC HOSE DIAGRAM HOPPER LIFT ...

Page 220: ...2 2 General Purpose Motors ...

Page 227: ......

Page 228: ......

Page 229: ......

Page 230: ......

Page 248: ...ENGINE DIESEL 6 2 6200D 330395 8 99 ...