HYDRAULICS

5--5

6100 G/LP 330235 (9--00)

HYDRAULIC FLUID

The quality and condition of the hydraulic fluid

plays a very important role in how well the

machine operates. TENNANT’s hydraulic fluid is

specially selected to meet the needs of TENNANT

machines.

TENNANT’s hydraulic fluid provides a longer life

for the hydraulic components.

TENNANT part no.

Ambient

Temperature

65870

below 7

_

C (45

_

F)

If a locally-available hydraulic fluid is used, make

sure the specifications match TENNANT hydraulic

fluid specifications. Using substitute fluids can

cause premature failure of hydraulic components.

ATTENTION! Hydraulic components

depend on system hydraulic fluid for

internal lubrication. Malfunctions,

accelerated wear, and damage will result

if dirt or other contaminants enter the

hydraulic system.

HYDRAULIC HOSES

Check the hydraulic hoses every 200 hours of

operation for wear or damage.

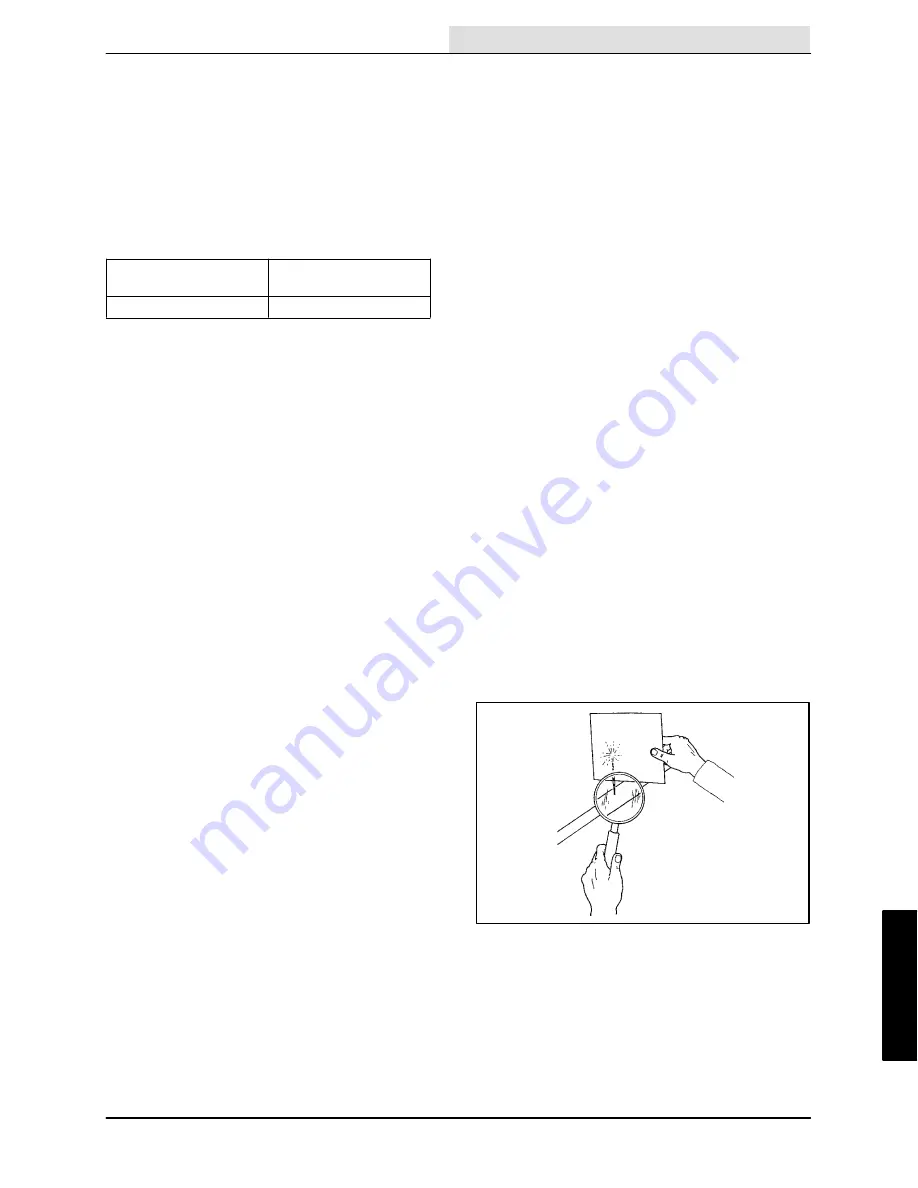

Fluid escaping at high pressure from a very small

hole can be almost invisible, and can cause

serious injuries.

See a doctor at once if injury results from

escaping hydraulic fluid. Serious infection or

reaction can develop if proper medical treatment

is not given immediately.

FOR SAFETY: When Servicing Machine,

Use Cardboard To Locate Leaking

Hydraulic Fluid Under Pressure.

If you discover a fluid leak, contact your

mechanic/supervisor.

Summary of Contents for 6100 G/LP

Page 1: ...330235 Rev 02 9 01 Service Manual 6100 G LP ...

Page 4: ...GENERAL INFORMATION 1 2 6100 G LP 330235 9 01 ...

Page 18: ...CHASSIS 2 2 6100 G LP 330235 9 00 ...

Page 27: ...CHASSIS 2 11 6100 G LP 330235 9 00 7 Remove the hub assembly from the tire assembly ...

Page 72: ...CHASSIS 2 56 6100 G LP 330235 9 00 ...

Page 74: ...SWEEPING 3 2 6100 G LP 330235 9 00 ...

Page 152: ...ELECTRICAL 4 2 6100 G LP 330235 9 00 ...

Page 175: ...ELECTRICAL 4 25 6100 G LP 330235 9 01 ...

Page 176: ...ELECTRICAL 4 26 6100 G LP 330235 9 01 ELECTRICAL SCHEMATIC GAS 1 2 3 4 ...

Page 177: ...ELECTRICAL 4 27 6100 G LP 330235 9 01 ELECTRICAL SCHEMATIC GAS 1 2 3 4 ...

Page 178: ...ELECTRICAL 4 28 6100 G LP 330235 9 01 ELECTRICAL SCHEMATIC LP 1 2 3 4 ...

Page 179: ...ELECTRICAL 4 29 6100 G LP 330235 9 01 ELECTRICAL SCHEMATIC LP 1 2 3 4 ...

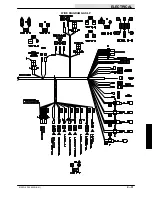

Page 180: ...ELECTRICAL 4 30 6100 G LP 330235 9 01 WIRE DIAGRAM GAS LP ...

Page 181: ...ELECTRICAL 4 31 6100 G LP 330235 9 01 WIRE DIAGRAM GAS LP ...

Page 182: ...ELECTRICAL 4 32 6100 G LP 330235 9 01 ...

Page 190: ...ELECTRICAL 4 40 6100 G LP 330235 9 00 ...

Page 192: ...HYDRAULICS 5 2 6100 G LP 330235 9 00 ...

Page 198: ...HYDRAULICS 5 8 6100 G LP 330235 9 00 9 Disengage the prop rod and close the seat support ...

Page 205: ...HYDRAULICS 5 15 6100 G LP 330235 9 00 10 Disengage the seat rod and close the seat assembly ...

Page 217: ...HYDRAULICS 5 27 6100 G LP 330235 9 00 HYDRAULIC SCHEMATIC ...

Page 218: ...HYDRAULICS 5 28 6100 G LP 330235 9 00 OUT IN B A B A HYDRAULIC HOSE DIAGRAM ...

Page 220: ...HYDRAULICS 5 30 6100 G LP 330235 9 00 ...

Page 221: ......

Page 222: ......

Page 223: ......

Page 224: ......

Page 225: ......

Page 226: ......

Page 227: ......

Page 228: ......

Page 229: ......

Page 230: ......

Page 231: ......

Page 232: ......

Page 233: ......

Page 234: ......

Page 235: ......

Page 236: ......

Page 237: ......

Page 238: ......

Page 239: ......

Page 240: ......

Page 241: ......

Page 242: ......

Page 243: ......

Page 244: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 249: ......

Page 250: ......

Page 252: ...ENGINE GAS LP 6 2 6100 G LP 330235 9 00 ...