OPTIONS

Tennant 1180 (03--04)

30

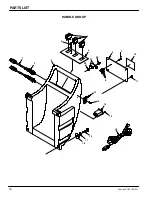

UPHOLSTERY TOOL GROUP

1

3

2

5 4

8

6

7

10

13

12

9

14

11

REF

PART #

DESCRIPTION

QTY.

∇

200545

D

ASM., TOOL, UPHOLSTERY,

SER 60

1

Y

1

200845

COVER, UPHOLSTERY TOOL

1

Y

2

200843

GASKET, COVER

1

Y

3

190631

D

KIT, SERVICE (VALVE ASM.)

1

Y

4

210226

D

VALVE, WATER/SOLUTION, LP

1

Y

5

201016

D

FITTING, JET, 1/8K

1

Y

6

200838

SCREW, #6--32X.75

4

Y

7

200840

TRIGGER, UPHOLSTERY TOOL

1

∇

ASSEMBLY

Y

INCLUDED IN ASSEMBLY

D

RECOMMENDED STOCK ITEMS

REF

PART #

DESCRIPTION

QTY.

Y

8

200844

D

HOSE, VACUUM W/O CUFFS

1

Y

9

200837

D

HOSE, SOLUTION

1

Y

10

200848

FITTING, BRS (3 PCS.)

1

Y

11

200842

FILTER, INLINE, COMPLETE

1

Y

12

200841

SCREEN ONLY, INLINE FILTER

1

Y

13

150606

FITTING, BRS, STR, PM04 X 1.38

HX NIP.

1

Y

14

150913

D

FITTING, QDC PF04 SER 60

1

Summary of Contents for 1180

Page 2: ......