Maintenance—

7T1

1A

Circuit

Board

Pin Replacement

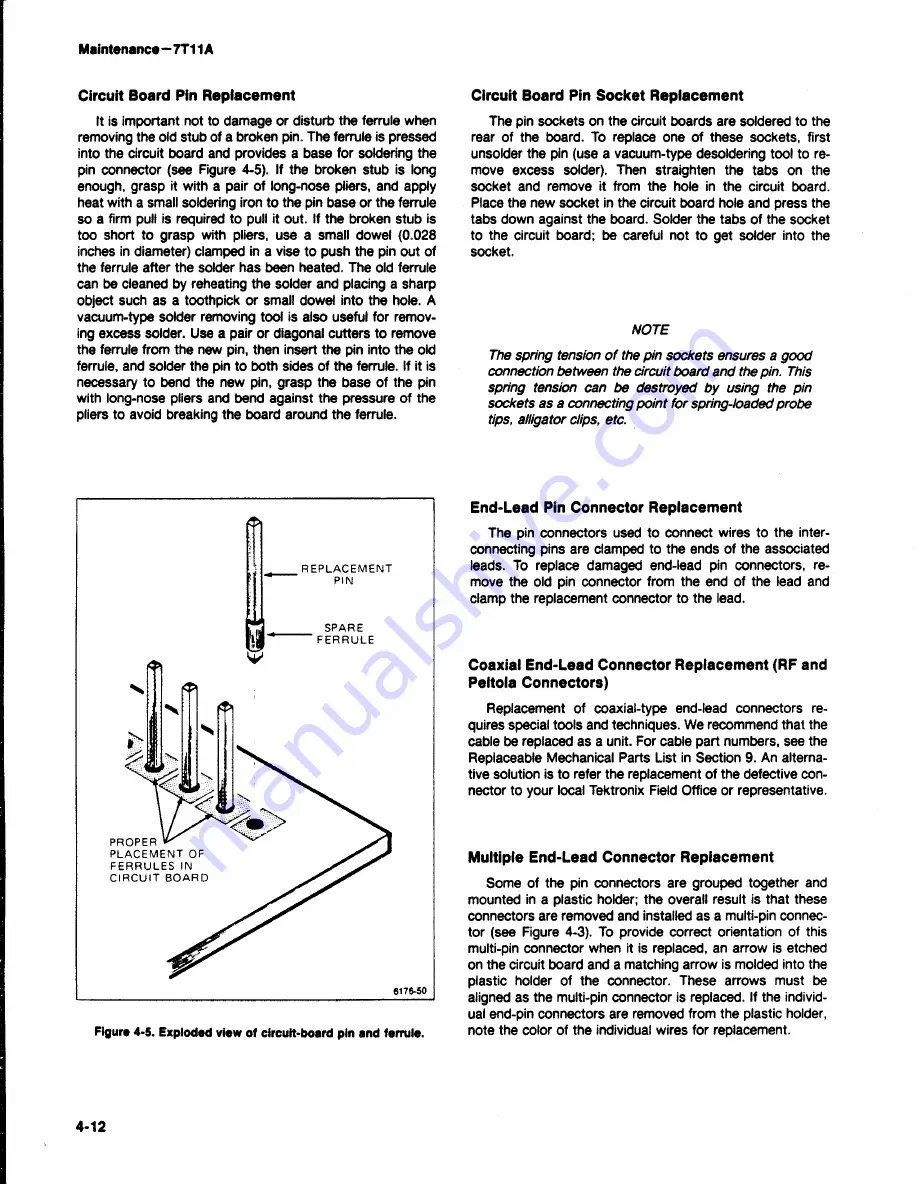

It is

important

not to damage

or disturb the ferrule when

removing the old stub of a broken pin. The ferrule is pressed

into

the circuit board and provides a base for soldering

the

pin

connector (see Figure 4-5). If the broken stub is tong

enough,

grasp

it with a pair of long-nose pliers, and apply

heat

with a small soldering iron to the pin base or the ferrule

so a firm pull is required

to pull it out.

If the broken stub is

too short

to

grasp with pliers,

use a small dowel (0.028

inches

in diameter) clamped in a vise to push the pin out of

the

ferrule after

the solder has been heated. The old ferrule

can

be

cleaned by reheating the solder and placing a

sharp

object

such

as a toothpick or small dowel into the hole. A

vacuum-type

solder removing

tool is also

useful for remov

ing

excess

solder.

Use a pair or diagonal cutters to remove

the

ferrule from the new

pin, then insert the pin into the old

ferrule,

and solder

the pin to both sides of the

ferrule. If it is

necessary to

bend

the new pin, grasp the base of the pin

with long-nose pliers and bend against the pressure of the

pliers

to avoid breaking

the board around the

ferrule.

Circuit

Board

Pin Socket Replacement

The

pin

sockets on

the

circuit boards are soldered to the

rear of the board. To

replace one of these

sockets,

first

unsolder

the pin (use a vacuum-type desoldering

tool

to re

move

excess

solder). Then straighten the tabs on the

socket

and remove it from the hole in the circuit board.

Place the

new

socket in the circuit board hole and press the

tabs down against the board.

Solder the tabs of the socket

to

the circuit board;

be careful not to get solder into the

socket.

NOTE

The

spring tension of the pin sockets ensures

a good

connection

between the circuit board

and the pin. This

spring tension

can be destroyed by using the pin

sockets as a connecting

point for

spring-loaded probe

tips, alligator clips,

etc.

Figure

4-5. Exploded view of circuit-board pin and ferrule.

End-Lead Pin

Connector Replacement

The

pin connectors used to connect wires to the

inter

connecting

pins are clamped to the ends of the associated

leads.

To replace damaged

end-lead pin connectors, re

move the

old

pin connector from the end of the lead and

clamp

the

replacement connector to the lead.

Coaxial

End-Lead Connector Replacement (RF and

Peltola

Connectors)

Replacement

of coaxial-type end-lead

connectors

re

quires

special tools and techniques. We

recommend that the

cable

be replaced as a unit. For cable part numbers, see the

Replaceable

Mechanical Parts List in Section 9. An alterna

tive

solution is to refer the replacement of the defective con

nector to your local

Tektronix Field Office or representative.

Multiple

End-Lead Connector Replacement

Some

of the pin connectors are grouped together and

mounted

in a plastic holder; the overall result is that these

connectors are

removed

and installed as a multi-pin connec

tor

(see

Figure

4-3).

To provide

correct orientation of this

multi-pin

connector

when

it is replaced, an arrow is etched

on

the circuit board and a matching arrow is molded into the

plastic holder

of the

connector. These arrows must

be

aligned

as

the multi-pin connector is replaced. If the individ

ual end-pin connectors are removed from

the plastic holder,

note the color of

the

individual wires for replacement.

4-12

Summary of Contents for 7T11A

Page 10: ...7T11A Instruction Manual 7T11A Sampling Sweep Unit viii ...

Page 39: ...Theory of Operation 7T11A 3 11 ...

Page 44: ...Theory of Operation 7T11A Figure 3 11 7T11A Blanking Logic 3 16 ...

Page 47: ...Theory of Operation 7T11A Figure 3 14 Random mode block diagram 3 19 ...

Page 179: ...y TRIGGER INPUT HF Sync Selected HF Sync Selected ...

Page 180: ...THIA SAMPLING SWEEP UNIT 6176 127 ...

Page 181: ...TRIGGER INPUT J TRIGGER INPUT 6 76 127 ...

Page 182: ...7T11A A3 TRIGGER BOARD Figure 8 3 A3 Trigger circuit ...

Page 183: ......

Page 185: ...Ext Trig ...

Page 186: ......

Page 187: ......

Page 189: ......

Page 191: ...Time position CW SEQUENTIAL OV Ext Trig Time position CW RANDOM ...

Page 192: ......

Page 193: ...TIME TO HEIGHT CONVERTER 176 12 5 TIME TO HEIGHT CONVERTER s 9 ...

Page 194: ...7T11A A1 LOGIC BOARD ...

Page 195: ......

Page 197: ...1000 Ω resistor between pins 17 18 of J641 ...

Page 198: ...NOTfcS UEADLE55 CAPACITOR l FOR DECOUPLING NETWORKS SEE H THIA SAMPLING SWEEP UNIT GITG I3Ö ...

Page 199: ......

Page 200: ...7T11A A4 INTERFACE BOARD Figure 8 6 A4 lnterface circuit ...

Page 201: ...b 8 6 A4 lnterface circuit board assembly ...

Page 203: ......

Page 204: ......

Page 205: ......

Page 206: ...5 ns DIV 5 ns DIV 5 ns DIV 5 ns DIV Ext Trig 5 ns DIV ...

Page 207: ......

Page 208: ......

Page 209: ...Ext Trig ...

Page 210: ......

Page 211: ......

Page 212: ......

Page 213: ......

Page 214: ......

Page 215: ... 7TII SAMPLING SWEEP UNIT W7G 135 ...

Page 216: ...W7G 35 TIMING SWITCHES TIMING SWITCHES ...

Page 218: ...OUTPUT CONNECTORS 136 OUTPUT CONNECTORS 0 ...

Page 219: ...PARTIAL A4 INTERFACE OARD Gl7 i I37 7T11A SAMPLING SWEEP UNIT ...

Page 220: ... 137 VOLTAGE DISTRIBUTION DECOUPLING VOLTAGE DISTRIBUTION DECOUPLING H ...

Page 221: ... 174 136 1T11R SAMPLING SWEEP UNIT ...

Page 222: ...FRONT PANEL SWITCHING ...

Page 223: ...TP884 TP658 Figure 8 7 Location of Logic adjustments A2 5 im R ...

Page 231: ...12 ...

Page 232: ...FIG 1 EXPLODED VIEW 7T11A ...

Page 234: ...F IG 2 ACCESSORIES 7T11A ...