29

Dial Test Indicator

Inspection procedure

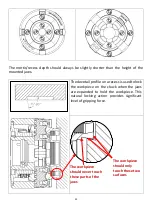

Lathe Spindle Inspection

Inspect the lathe spindle itself first before inspecting the chuck runout. The runout of

the chuck could be caused a misaligned spindle.

Note:

The tolerances specified below is only applicable to NOVA lathes. Lathes from other

manufacturers may have different tolerance standards therefore it is the best to

contact the lathe manufacturer to confirm the spindle tolerances.

Test

Number

Method

Image

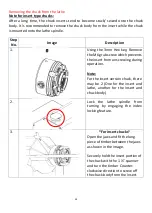

1.

Measure the radial runout of

the spindle itself by:

Locate the DTI on the register

part of the spindle as shown on

the image

Spin the lathe by hand

The runout measurement

should be ranging between:

-0.02mm ~ +0.02mm

(-0.00079” ~ +0.00079in)

Any reading exceeding this

value will be exceeding the

standard tolerances.