28

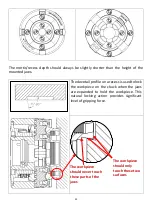

Chuck jams on lathe

spindle

This is a common problem with fixtures on a lathe. To

help prevent it try a plastic or fiber washer between

insert/chuck and spigot shoulder of spindle. Greasing of

insert face and spindle can also help.

Note

Use of plastic spindle washers could affect accuracy.

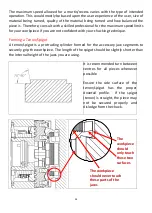

Safe Lock Woodworm

screw creeps forward or

is not seated properly in

chuck

Ensure the Safe Lock Woodworm screw is placed

correctly between jaw slides and behind the jaws

Wooden tenon shifts

during turning

Check that the tenon area is made correctly for jaws to

grip. Check that the tenon is not oversized or

undersized.

See tenon operation instructions.

Use careful chisel techniques that do not exert

excessive pressure. Irregular rough wood blanks need

to be checked to see if there is enough jaw surface

contact.

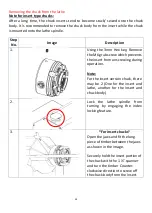

Wood blank does not seat

properly in internal

mortise mounting

Check the angle of the dovetail made in the mortise is

the same angle as the jaws. Make sure the bottom of

the recess is flat and square to face.

Check that the bowl is not incorrectly riding on the flat

shoulder of at the base of the jaws.

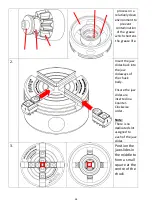

Chuck runout inspection procedure

The runout tolerance is specified at the chuck body and not on the workpiece.

Generally, wood is a flexible material which makes it an insufficient medium to

measure accuracy. Radial runout values on a workpiece is amplified as the length of

the workpiece increases therefore the measurements must be taken at the chuck

body to standardize the procedure.

Equipment Required

A Dial Test Indicator (DTI) is required to inspect and quantify the level runout on the

chuck.