Teikoku USA | Chempump

Instruction Manual G-Series

11

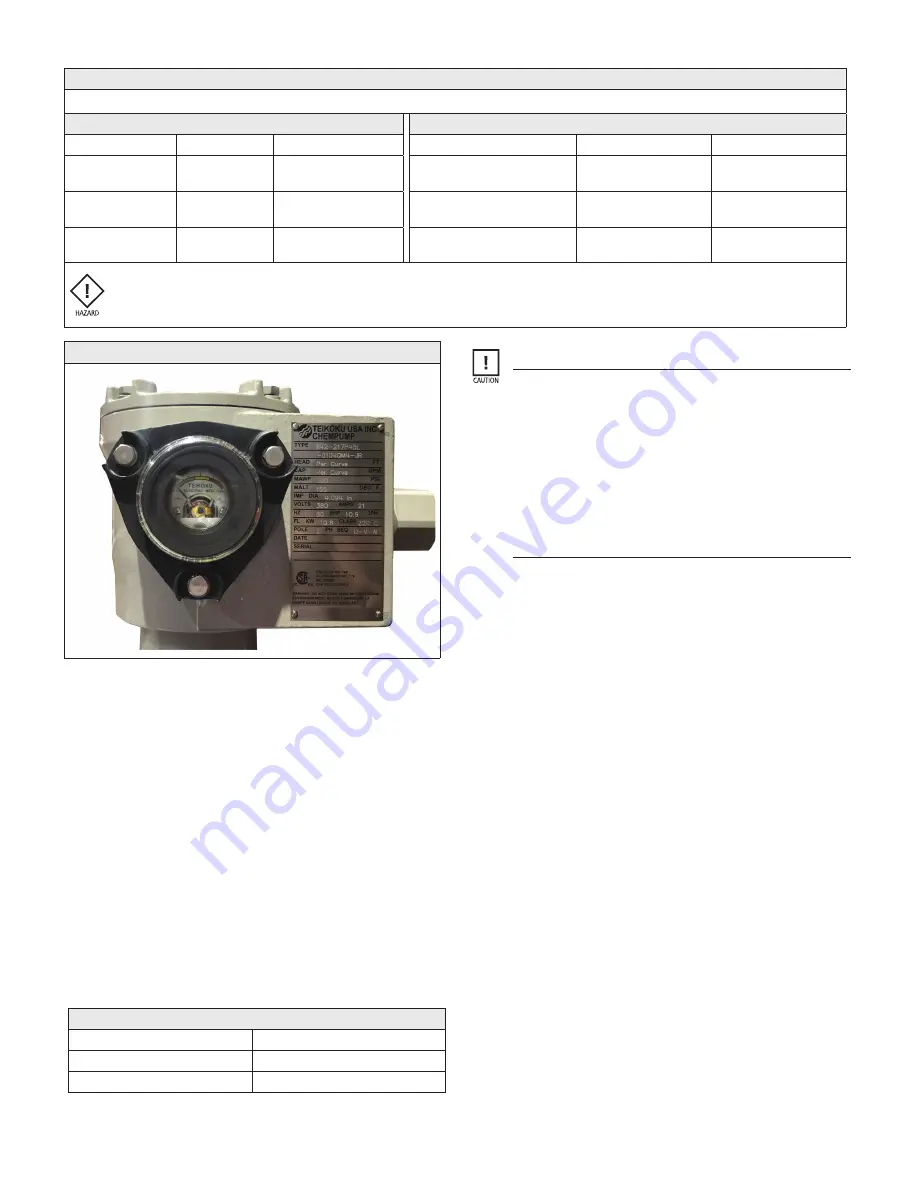

Figure 2-2. Teikoku TRG Bearing Wear Monitor

Table 2-1. Conditions Indicated on the TRG Meter

The TRG meter has a colored scale which is divided into three zones: Green (0 to 0.5), Yellow (0.5 to 0.75), Red (0.75 to 1)

AT TRIAL OPERATION

DURING OPERATION

Indication

Condition

Solution

Indication

Diagnosis

User Actions

Full scale

incorrect wiring

change power cable

connection

Green

Good

No action

Yellow to Red

phase failure

check connection of

cables

Yellow or scale increase of

> 0.3 from initial indication

Bearings worn to

caution level

Plan routine

maintenance

Green

normal

connection is correct

Red or scale increased of

> 0.5 from initial indication

Immediate

maintenance required

Shutdown immediately

and replace worn parts

Hazard!

Do not operate if TRG meter condition is RED.

using the TRG meter, use the color change (Green, Yellow, Red)

as a reference. If the increase of TRG readings is 0.3 or more, stop

the pump and check bearings.

The Teikoku Rotary Guardian (TRG) signal is affected by motor

load. Changes in operating frequency or hydraulic load may in-

crease or decrease signal.

Keeping records of the TRG meter reading in conjunction with

motor amp readings will provide a good indication of when the

pump will require maintenance.

2.3.2 Thermal Cutout

Unless otherwise specified, all G-Series pumps are fitted with

thermal cutouts. The cutout is a heat-sensitive bimetallic switch,

mounted in intimate contact with the stator windings. It is to be

wired in series with the holding coil in the starter box. Refer to

Table 2-2

for TCO maximum holding coil currents.

Table 2-2. TCO Maximum Coil Currents

115 Volt

3.1 Amps

230 Volt

1.6 Amps

460 Volt

0.8 Amps

Caution!

The thermal cutout switch does not provide protection

against fast heat buildup resulting from locked rotor con-

ditions, single phasing, or heavy overloads. This protection

must be provided for by the current overload relay heaters

in the magnetic starter. The rating of the heaters should

be high enough to avoid nuisance cut outs under running

loads, but must not be oversized. Refer to

Table 2-3

for

starting and running electrical characteristics. It is recom-

mended that “quick trip”, class 10 or less, type heaters

be used.

2.3.3 Starting Equipment

Motor starters (normally not supplied with G-Series pumps)

should be sized to handle the load required per the National Elec-

trical Code (NEC). Start KVA, Full Load KW, Full Load amps and

Full Load KVA data are listed in

Table 2-3

.

Thermal overload protective devices in the starters should be sized

for the amperage shown on the product nameplate. DO NOT size

the thermal overload protective device in excess of 10% of full

load amp rating. In order to provide complete protection for G-

Series motors under all conditions, it is recommended that “quick

trip” (Class 10) type thermal overload protective devices be used

in the starters where available. Standard type thermal overload

protective devices can be used if these “quick trip” type thermal

overload protective devices are not available. Standard thermal

overload protective devices provide adequate protection for G-

Series motors under starting or normal running conditions, but

require a greater length of time than “quick trip” type thermal

overload protective devices to cut out. This may not protect the

meter if the motor is subject to locked rotor or overload condi-

tions. Also, see

Tables 2-3, 2-4, 2-5,

or

2-6

for additional electrical

wiring data for the most common G-Series motor sizes to assist in

the electrical installation of the unit.

2.3.4 Variable Frequency Drive (VFD) Power Supply

G-Series pumps can be operated with a VFD power supply. The

VFD should be a Pulse Width Modulated Drive selected for the

appropriate voltage class of the motor, i.e. 400V class for 460V

motors, and suitable to handle the full load current of the motor.

The VFD should always be sized based on full load nameplate