Model KT14000 power casing tong maintenance and operation manual

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

9

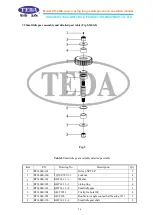

feel strength properly and tighten the nut.

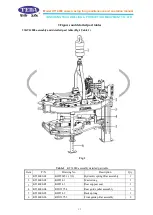

4.3.2Door latch adjustment

During normal operation of the tong, the left door latch may experience wear which will cause the door to

develop a loose fit at the latch. When this occurs, an adjustment can easily be made to assure a secure door

fit. This is accomplished as follows (see illustration below):

Located at the top face of the left door is a latch cam plate which has eight positioning holes located on a

360 degree bolt circle. To make any adjustment in door alignment, the 3/8" hex head bolt located at the top

and bottom latch shaft sleeve should be removed first, then use a wrench to rotate the latch shaft and shaft

sleeve, when desired alignment is achieved, the 3/8" hex head bolt should be tightened.

Note:

It is important to keep a secure fit at the doors as this helps maintain proper gear alignment, reduces

possibility of impact tensional stress occurs in the gear case and assure safety to operation personnel.

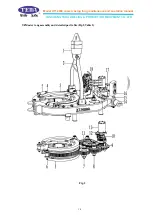

4.3.3Brake band adjustment (see illustration):

、

As the tong is used, it becomes necessary at times to adjust the brake bands to provide a smoother and more

Brake band

Hexagon nut