Model KT14000 power casing tong maintenance and operation manual

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

6

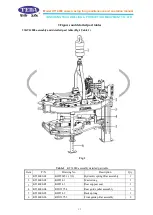

d.Shift the transmission into low gear. Pull the hand control valve rod make the casing tube thread

completely loosen.

e.Shift the transmission into high gear. Pull the hand control valve rod make the casing tube thread

completely unscrewed to the end.

f.Unlatch the door and remove the tong from pipe.

3.3.4

Working Process

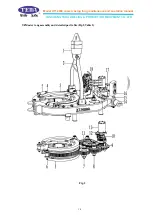

(1)The power station must be shut down when dismounting the jaws, in case of accident.

(2)Make sure the power tong is properly leveled

(3)Ensure that all tong hydraulic hoses are correctly connected

(4)Pay attention to the specification of the jaws when installing.

(5)Changing gear is not allowed during operation.

(6)Only when the safety door is shut down, the gear notch can start turning, in case of damage to the

operators.

(7)Check the clearance between safety door and shell frequently. Adjust the clearance make the door work

normally. If the clearance is too much will damage the power tong.

(8)Check the lifting rope and tail rope for safe reliability.

(9)Adjust the Relief valve of the hydraulic power station above 2500PSI(17.2MPa),the pressure regulating

handle will be deadlocked

。

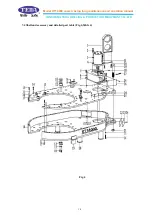

(10)When the tong is operating above 36,000ft.lb,ensure that both idler drive gears are engaged with the

main gear.

Note:

Be sure the doors are closed and securely latched before power unit is started to insure safety for

operation personnel.

Use start up procedures as recommended by the power unit engine operator’s manual. Prior to starting

engine, an inspection should be made to assure proper lube oil level in the engine and hydraulic oil level in

the hydraulic reservoir. Open the by-pass valve on the hydraulic system. Check all pressure and return line

hose connections to make sure they are securely installed.

After the hoses are checked, start the engine and allow it to idle until warm. After the power unit engine has

been started and hydraulic oil has circulated for approximately 10 minutes, slowly close the by-pass valve

which will allow oil to circulate through the hoses and to the tong. Place the tong gear shifter in low gear

and rotate the tong slowly forward and then reverse with the throttle valve control lever. Once this has been

done and the proper size jaws have been installed, the tong is then ready to run pipe.

3.3.5

General comments

It is recommended that torque not exceed 36,000ft.lbs. Unless both idler gears are in drive position. This

will enhance the life expectancy and dependability of the tong. When operating the tong at high gear, it is

recommended to frequently check the tightness of the door and make periodic adjustments to assure a

secure door fit.

For safety of rig personnel, make sure the door is securely closed and latched at all times.

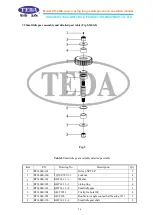

When make-up integral (shouldered) joints, it is essential to make up the last turn of the threads in low gear.

This reduces the tendency of an instant stop or a sudden increase in torque, which induces high stresses to

the gear train.

hen pulling a string, do not employ the “snap break” method of breaking out joints. By definition, the “snap

break” method is a procedure used by some operations to break-out connections.