27

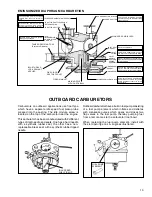

STARTER CHECKING AND SERVICE.

Remove nuts

at both ends of the starter and take off rear end cap.

CHECK BRUSHES.

Before removing the armature,

check brushes for wear. Make sure brushes are not

worn to the point where the brush wire bottoms out

in the slot of the brush holder. Brush springs must

have enough strength to keep tension on the brushes

and hold them against the commutator.

If brushes need replacement, remove by unhooking

the terminals or cutting the connections and then

resoldering. If the brush card is warped from overheating,

replace the card assembly.

TROUBLESHOOTING STARTERS.

STARTER DOES NOT FUNCTION.

Check for:

1. No current to the starter caused by faulty connections

or blown circuit breaker.

2. Faulty safety switches, ignition, starter switch, or

solenoid.

3. Engine locked up or parasitic load on engine.

4. Shorted, open, or grounded field coil.

5. Open, shorted, or bent armature.

6. Brushes sticking or damaged.

7. Dirty or oily brushes or commutator.

STARTER CRANKS ENGINE SLOWLY.

Check for:

1. Parasitic load or tight engine.

2. Worn brushes or weak brush springs.

3. Dirty, oily, or worn commutator.

4. Worn bearings in cap assemblies.

5. Defective armature.

STARTER SPINS, ENGINE DOES NOT CRANK

. Check

for:

1. Pinion gear sticking on shaft.

2. Damaged pinion or flywheel ring gear.

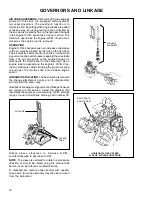

CHECK FIELD.

Using a continuity light or ohmmeter,

check the field by attaching one lead to each field coil

connection. Continuity should exist between these two

points. Check continuity between each field coil

connection and the starter housing. No continuity should

exist.

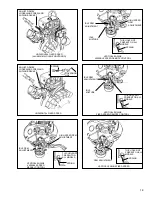

ARMATURE CHECK.

If the commutator bars are glazed

or dirty they can be turned down on a lathe. While

rotating, hold a strip of 00 sandpaper lightly on the

commutator, and moving it back and forth. (Do not

use emery cloth). Recut the grooves between the

commutator bars to a depth equal to the width of the

insulators.

FIELD COIL

CONNECTORS

CONNECTION POINTS

OF POWER CORD LEADS

Use a continuity tester to make certain no continuity

exists between the commutator (copper) and the iron

core of the armature, rotate armature and check out

all commutator bars.

The armature can be thoroughly checked with a growler

if available.

Summary of Contents for AH520 -

Page 67: ...64...