10

The float dampening spring on the HIGH TILT FLOAT

STYLE carburetor has an extended end which must

point toward the choke end of the carburetor.

cleaner and compressed air. With the choke plate and

shaft removed, blow compressed air through the high

speed air bleed located just behind the lower choke

shaft bearing and immediately in front of the venturi

to remove any dirt that may have accumulated.

Blow compressed air through all of the passages, making

sure they are free of dirt, varnish or foreign material.

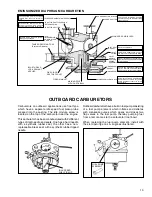

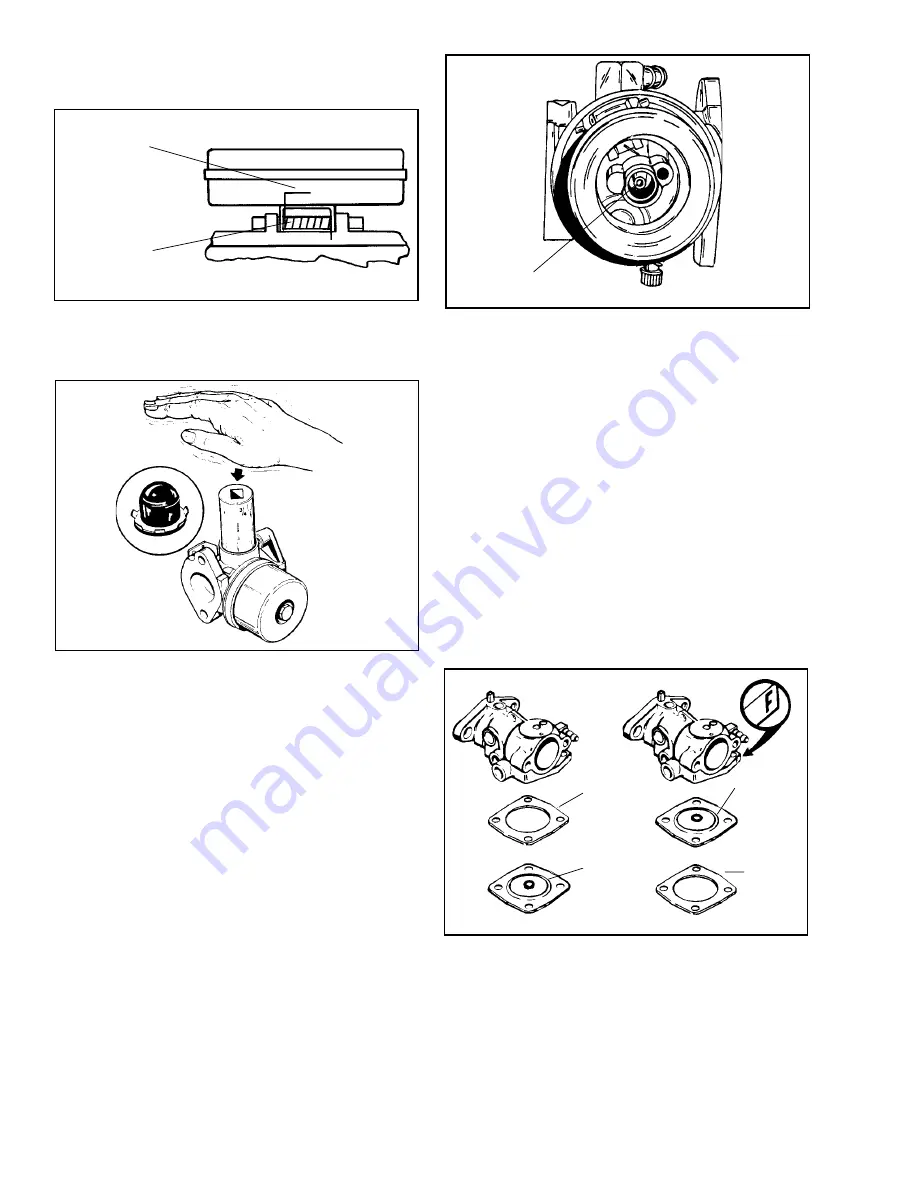

DIAPHRAGMS.

Inspect diaphragms for cracks, tears

or brittleness. Replace if necessary. Rivet head on

diaphragm must always face toward the inlet needle

valve.

If the carburetor has an "F" designation on the casting,

it will identify the installation sequence of the gasket

and diaphragm on the carburetor. "F" designated

carburetors have the diaphragm installed first then the

gasket then the cover. If there is no designation, the

sequence is gasket, diaphragm and cover.

INLET NEEDLE AND SEAT.

(Diaphragm Carburetors)

POINTS TOWARD

CHOKE END

FLOAT DAMPENING

SPRING

PRIMER BULB.

To install, start the retainer and bulb

into the casting with the retainer tabs pointed out. Firmly

push the bulb and retainer into position using a 3/4"

(19mm) deep well socket.

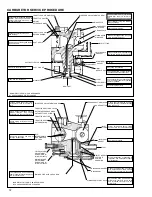

CLEANING CARBURETOR BODY.

When removing

choke and throttle shafts, check shafts and bearings

in carburetor body for wear. Any looseness in these

areas can cause dirt to enter the engine resulting in

premature wear. If dust seals are present, they should

be positioned next to the carburetor body. Install the

dust seal, metal washer, and finally the return spring.

Welch plugs should be removed for proper cleaning

of the carburetor (See welch plug service at the beginning

of this section). When all accessories and shafts have

been removed, soak the carburetor in carburetor cleaner

for a maximum of 30 minutes. Blow out all passages

with compressed air in the opposite direction of normal

fuel flow.

The carburetor body on non-emission carburetors contains

a main nozzle tube pressed into the carburetor body

to a predetermined depth within the venturi of the

carburetor. DO NOT attempt to remove this main nozzle.

Any movement of this nozzle will seriously affect the

metering characteristics of the carburetor. (Emissions

carburetors have a serviceable plastic nozzle.)

Clean the well surrounding the main nozzle with carburetor

MAIN NOZZLE

DO NOT ATTEMPT TO REMOVE

GASKET

RIDGE AND

RIVET

HEAD UP

GASKET

RIDGE AND

RIVET HEAD UP

Summary of Contents for AH520 -

Page 67: ...64...