TECMASCHIN

6

1. Wrap the package to be wrapped with the strapping tape so that the

ends overlap.

2. Lift the strap slightly so that you can drive under the strap with

the strapping tool. Hold the lever while doing this. Release the lever when

the tool is in the correct position.

3. Press the tensioning knob. After you have reached the desired clamping

force, release it again.

4. Weld the strap by pressing the welding button. Once the strap is cut,

you can remove the strapping tool.

5. Return the tensioning knob to the upper position by guiding the tensioning

knob upwards and move the device away from the packaging tape.

6. Check the strapping again for any damage or weak points.

Check the functionality of the device regularly. Pay particular attention to correct welding and Tension, as deviations may

occur here during prolonged use. In these cases, adjust the controllers. Remove the battery before any repair work in order

to exclude possible injury hazards.

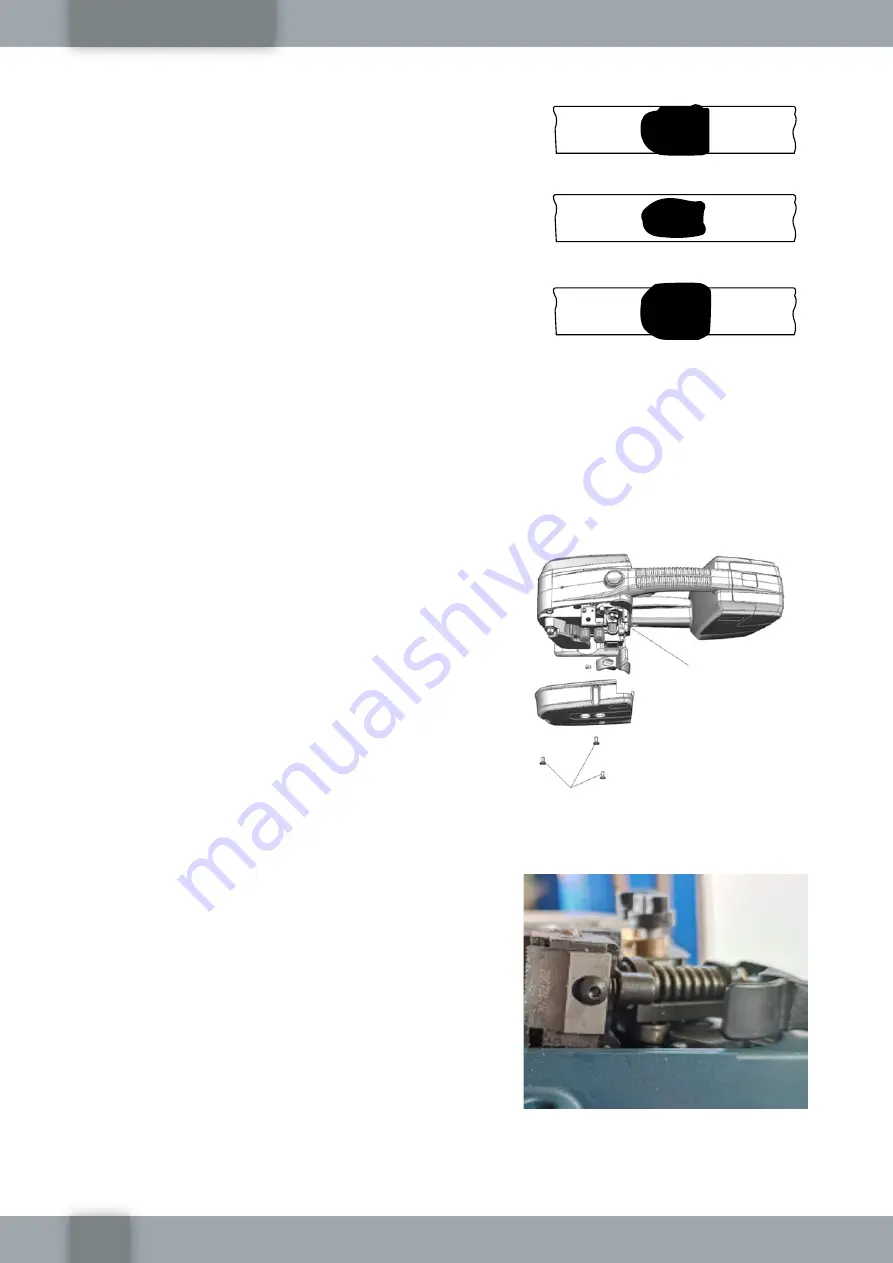

ADJUSTMENT OF THE WELDING PRESSURE

If the welding pressure is too low or too high, this can

lead to faulty welding.

This circumstance depends on 2 factors:

The material thickness and the strip material itself.

1. Remove the battery from the housing of the device.

2. Open the left cover of the housing by loosening the

3 M4 screws.

3. Move the weld knob to the down position to expose

the silver M6 nut above the tension spring.

4. Tighten the nut to decrease the welding power.

To increase loosen the nut slightly.

STRAPPING PACKAGES

MAINTENANCE AND REPAIR

Correct welding

Welding time too short

Welding time too long

M4 screws

M6 nut

CUTTING FORCE ADJUSTMENT

If the strap is not cut or the blade cuts both strands of the strap,

it is necessary to adjust the cutting force.

1. Remove the battery from the housing of the device.

2. Open the left cover of the housing by loosening the 3 M4 screws.

3. Loosen the M4 screw directly on the blade of the device with

an Allen key.

4. Remove the blade of the device.

5. Replace the spring behind it.

6. Reassemble the device in reverse order.

Tip:

The spring, which is already installed in the device, is used for

welding with PET tape. If you use PP tape, replace the spring with

the enclosed one before the first use.