31

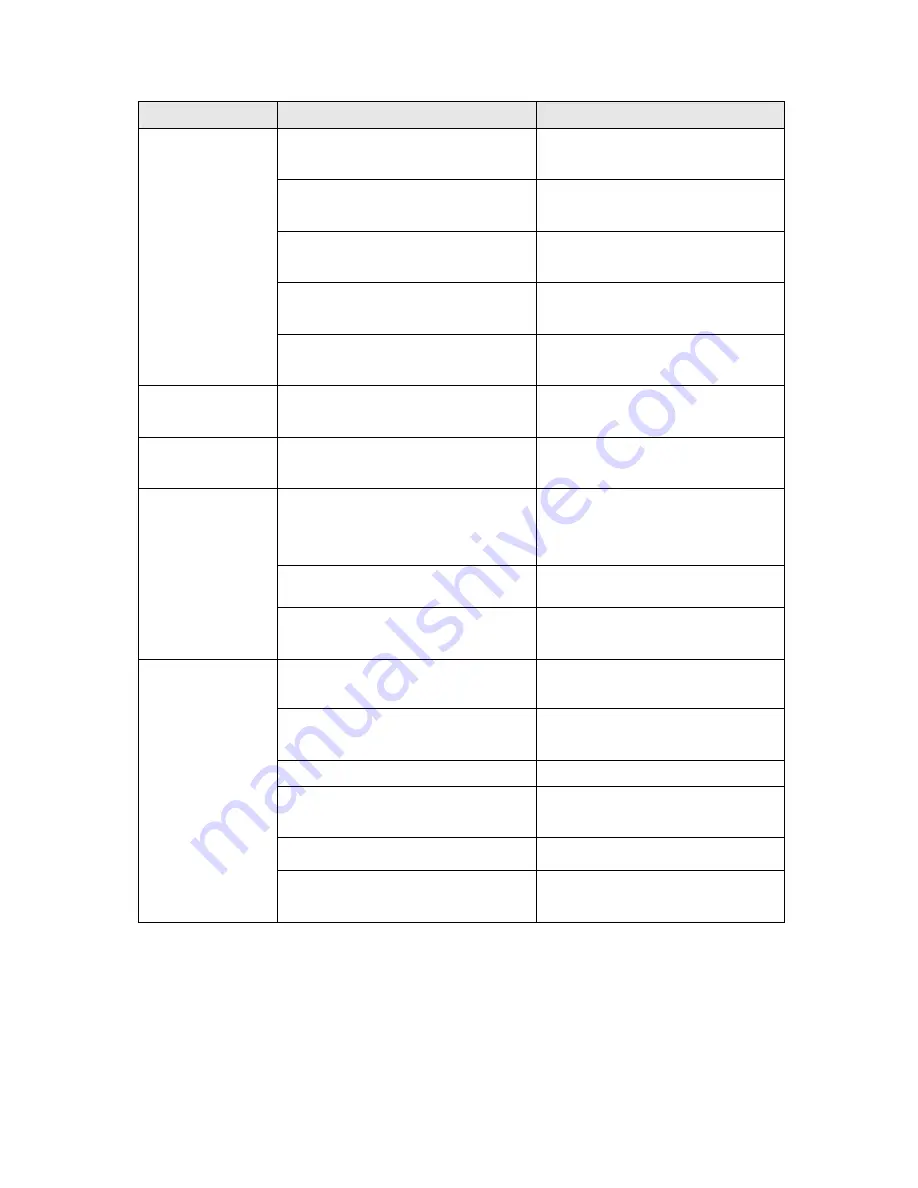

5.2 Print Problem

Problem

Possible Cause

Recovery Procedure

Check if interface cable is well

connected to the interface connector.

Re-connect cable to interface.

The serial port cable pin configuration is

not pin to pin connected.

Please replace the cable with pin to pin

connected.

The serial port setting is not consistent

between host and printer.

Please reset the serial port setting.

The port specified in the Windows driver

is not correct.

Select the correct printer port in the

driver.

Not Printing

The Ethernet IP, subnet mask, gateway

is not configured properly.

Configure the IP, subnet mask and

gateway.

No print on the label

Label loaded not correctly.

Follow the instructions in loading the

media.

Continuous feeding

labels

The printer setting may go wrong.

Please do the initialization and

gap/black mark calibration.

Gap/black mark sensor sensitivity is not

set properly (sensor sensitivity is not

enough)

Calibrate the gap/black mark sensor.

Make sure label size is set properly.

Set label size exactly as installed paper

in the labeling software or program.

Paper Jam

Labels may be stuck inside the printer

mechanism near the sensor area.

Remove the stuck label.

Top cover is not closed properly.

Close the top cover completely and

make sure the right side and left side

levers are latched properly

Wrong power supply is connected with

printer

Check if 24V DC output is supplied by

the power supply.

Check if supply is loaded correctly.

Reload the supply.

Check if dust or adhesives are

accumulated on the print head.

Clean the print head.

Check if print density is set properly.

Adjust the print density and print

speed.

Poor Print Quality

Check print head test pattern if head

element is damaged.

Run printer self-test and check the print

head test pattern if there is dot missing

in the pattern.

Summary of Contents for DT039-50

Page 1: ...USER S MANUAL DT2205 DT039 50 DIRECT THERMAL BAR CODE PRINTER ...

Page 4: ...i ...

Page 14: ...8 z Loading path for roll labels DT2205 model DT039 50 model ...

Page 16: ...10 Note Please calibrate the gap black mark sensor when changing media ...

Page 20: ...14 Note Please calibrate the gap black mark sensor when changing media ...

Page 42: ......