RUN 600 XTPRO: Service & Maintenance Manual - rev. 1.3

Page 8.1

8. ADJUSTMENTS

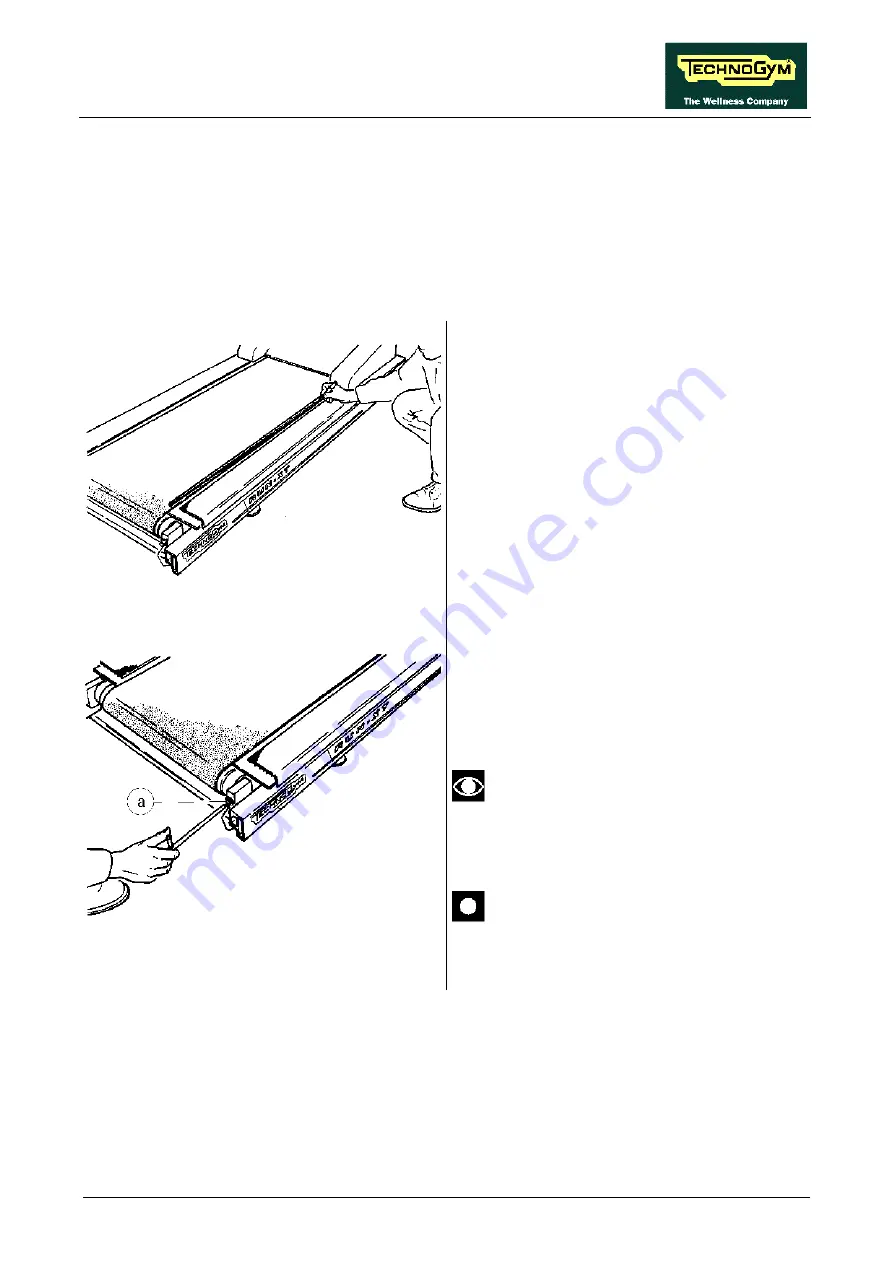

8.1. TENSIONING A NEW TREAD BELT

Figure 8.1-1

1. After assembling the new tread belt, place a

tape measure along the right hand edge of the

tread belt, and use a pen make two reference

marks on the tread belt at a distance of

exactly 1 meter from each other.

Figure 8.1-2

2. Lock down the right hand tread belt tensioner

screw

a

until the distance between the

reference marks increases by 7 mm.

3. Lock down the left hand tread belt tensioner

screw until the driven roller is aligned with

the crosspiece.

After completing this procedure, any

further adjustments should be

performed using only the left-hand

tensioning screw.

After completing this procedure, check

the centering of the tread belt as

instructed in paragraph 8.3.

Summary of Contents for RUN 600 XTPRO

Page 1: ...SERVICE MAINTENANCE MANUAL REV 1 3...

Page 2: ......

Page 4: ......

Page 24: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 2 14 Page intentionally left blank...

Page 36: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 3 12 Page intentionally left blank...

Page 38: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 4 2 Page intentionally left blank...

Page 82: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 6 42 Page intentionally left blank...

Page 126: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 8 10 Page intentionally left blank...

Page 156: ...RUN 600 XTPRO Service Maintenance Manual rev 1 3 Page 11 14 Page intentionally left blank...

Page 157: ......