7b.On Wheels-Free Hoist

(A) Remove the column hooks, air cylinders,

springs and swivel blocks from the outside of

both crossmembers. Remove the air lines from

inside the crossmembers.

(B) Line up the holes in the tracks and

crossmembers, fit the four extension U-brackets

using the M10 x 25 mm long grade 8.8 screws

supplied with the wheels-free beam kit. Do not

tighten yet.

(C) Place the wheels-free crossmembers into the U-

brackets over the locating pins.

Note:

The crossmembers are not the same. The

operating handles must be on the power column side

of the hoist.

(D) Engage the interlock pins to lock the wheels-

free crossmembers and the hoist crossmembers

together. Adjust the U-brackets so the interlock

pins engage freely. Now fully tighten the M10

screws. Remove the wheels-free crossmembers

to tighten all the screws.

(E) Fit the wheel stops and drive-on ramps to the

outside of the U-brackets with the M10 x 20mm

long screws and nuts. Refer Fig.C. Refit the

wheels-free crossmembers.

wheels-free crossmember, down into the U-

brackets so that the crossmember is not leaning

out and does not wobble.

(G) Adjust the locating screws on the top inside

edge of the wheels-free crossmembers until the

crossmember is not leaning inward. Check the

interlock pins still engage freely.

8. Carefully remove the clutches (Fig. D) and the cable

retainers from the end of the crossmembers and

feed the cables through the ends of the

crossmembers and around the cable pulleys. Refit

the cable retainers. Place a clutch spring and guide

ferrule over the guide pin on the clutch and refit the

clutch to the crossmember.

Note:

The four clutches are preset for each corner and

must not be mixed up or damaged in any way.

9. Remove the clutch rods from the columns and offer

each column up to the crossmembers so that the

notches are on the outside in line with the column

hooks on the crossmembers.

Note:

The power column (which has two holes in the

back) must go on the crossmember beside the

hydraulic hose.

(A) On Wheels-Free Hoist

Fit a coiled hose, bulkhead connector and

elbow connector to the column furthest from the

power column.

(B) On All Hoists

Connect the bottom of the coiled tube inside the

column(s) to the connector(s) at the end of the

crossmember(s) inside the column. Feed the

guide tube(s) down through the top of the

column(s)and through the middle of the coiled

tube(s).

10.Remove the plastic plug from the end of the

hydraulic hose and pull hard on the cables to

extend the cylinder. Now feed the cable adjusting

screws through the top of each column and fit two

nuts to each screw. Leave the nuts loose.

11.Feed the clutch rods down through the top of the

columns. Hold the clutch square against the clutch

spring stop and lower the clutch rod through

the hole in the clutch and the guide bush just below

the clutch. Now check that the spring on the clutch

is still straight and is not buckled. Screw the clutch

rod into the base of the column while still holding

the clutch square. (If the clutch is not held square,

it will mark the clutch rod and cause the guide bush

to wear rapidly.) Tighten the nut on the top of the

rod sufficiently to tension the rod.

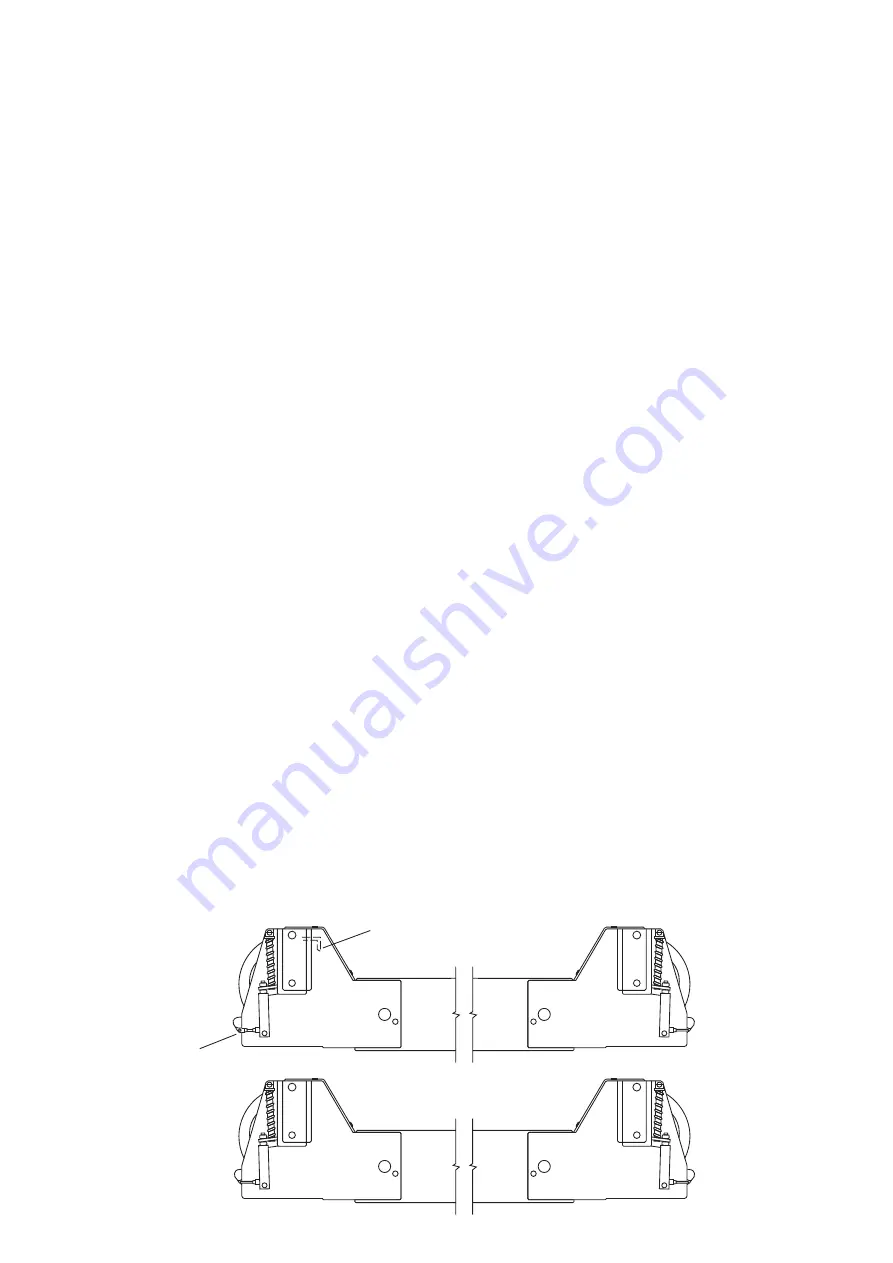

FIG. B

Power Crossmember

LIMIT SWITCH TRIGGER

TEE

CONNECTOR

Slave Crossmember

(F) Adjust the screws in the bottom outer edge of the

Summary of Contents for TEC 4000

Page 1: ...4000 4 Post 4 Tonne Hoist TEC4000 TEC4011 Wheels Free Beams...

Page 18: ......

Page 19: ......

Page 23: ...Page 22 Note...