1 5

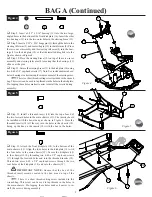

Figure 37

BAG D (Continued)

Figure 37

!

Step 18. While holding the outdrive/diff half (77) with the

Allen wrench inserted, carefully place the two outdrive/diff halves

(77) together.

!

Step 19. Make sure that the slot in the diff screw (84) is lined

up with the slot in the outdrive/diff half (77) and that the Allen

wrench is inserted in the slot in the diff screw (84).

!

Step 20. Hold the diff so that the outdrive/diff half (77) with

the diff nut carrier (73) is pointing up. Slowly turn the top diff

half clockwise to thread the diff screw (84) into the 4-40 mini

locknut (7) in the diff nut carrier (73). Thread the two halves

together until the screw just starts to snug up.

*NOTE: If the screw will not thread into the nut, make sure that

the nut carrier is pushed all the way into the outdrive/diff half.

!

When tightening the diff, tighten the screw a little and

then “work” the diff a little. Then tighten the diff a little more

and “work” the diff again. Continue this until the diff is tight.

This will ensure proper seating of all the parts in the diff

assembly.

!

Step 21. Tighten the diff until the gear (81) cannot be turned

while both of the outdrives (77) are being held. Final diff

adjustment should be made after completion of the car.

84

81

77

73

Summary of Contents for XXX-T Matt Francis Edition

Page 2: ......