replacing. Before removing the hammers note the

size and position of the spacers. Remove the bolt

retaining the hammers and either turn them or

reposition them using the unused pivot hole. Refit the

bolt making sure the spacers and blade bushes are

replaced in the correct order.

11.4 Drum removal

NOTE.

This operation requires two persons.

To remove the drum, dismantle the belt guards then

slacken and remove the belts. Swing the motor

assembly around so that it is well clear of the drum

and restrain it in that position. Turn the drum so that

the large hole in its periphery is at the top. Suspend

the drum from the spiral bar inside the lifting hole

using a certified lifting strop or chain with a load rating

in excess of 520kg.

Remove the two lower rear drum retainers and roller

guards so that is it possible to slide the drum

rearwards. Slacken the two bolts holding the top

bearing channel in place and carefully remove it,

ensuring that the loader is just taking the weight of the

drum as the bolts are loosened. Raise the drum

slightly and slide it rearwards, away from the machine.

Reassembly is a reverse of the above procedure.

11.5 Drum mountings

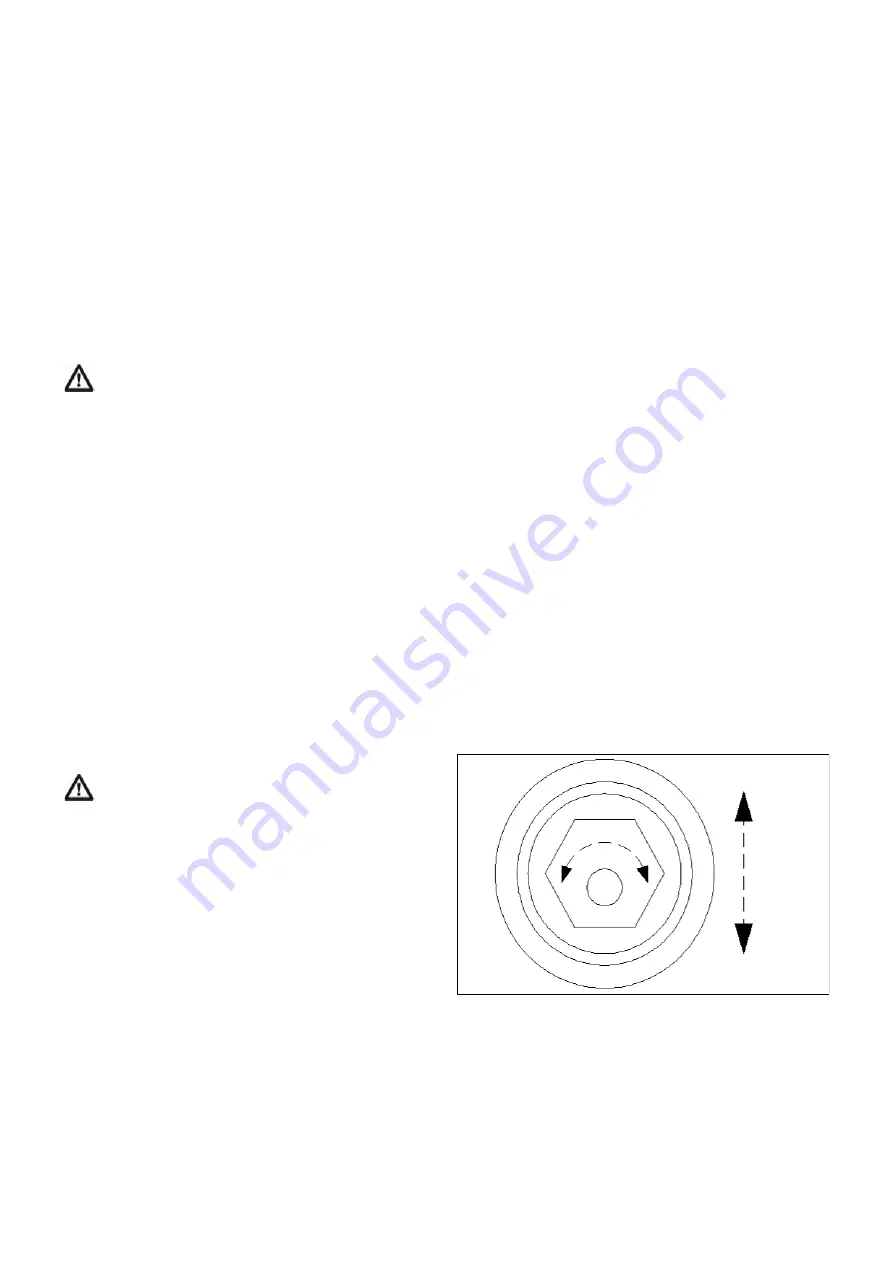

The lower rollers which support the drum are mounted

on eccentric hexagonal bosses - see Fig. 6. By

rotating these bosses, it is possible to centralise the

drum and adjust the clearance between the drum and

back plate at the bottom. The roller at the top of the

drum can be adjusted by moving the channel in its

slots. No adjustment is normally required as the

rollers are correctly positioned during factory

assembly. The clearance between the drum and back

plate should be 10 - 15mm.

Fig. 6 Eccentric Drum Mountings

11.6 Screen replacement (404M & 505M only)

Undo the six bolts retaining the screen to the back

plate. Rotate and slide the screen towards the rear of

the machine until it clears the rotor. Select the screen

to give the desired chop length and fit in the reverse

order of the above.

Fan speed can be controlled using the control knob at

the base of the oil cooler. Turning the knob in a

clockwise direction reduces fan speed.

Should oil temperature increase to 45 degrees Celsius

the oil cooler will automatically begin to operate. The

cooler will automatically reverse for a short time every

fifteen minutes to keep the cooler screen clear of

debris.

To stop fan operation, reduce PTO speed gradually

and when at idle disengage the PTO. Allow 3 minutes

for the rotor and fan to stop turning, turn the tractor

engine off and remove the ignition key before

disconnecting ducting from the fan outlet.

9.4 Blockage removal

WARNING.

Never begin to unblock a machine

until the PTO has been disengaged, the engine

stopped, the key removed from the ignition, and the

machine has come to rest.

Should the fan or ducting become blocked, use the

blockage removal tool loosen material inside and pull it

out.

10.0 USE ON THE PUBLIC HIGHWAY

If the machine is to be transported along the public

highway (any road where the public have access)

behind the tractor it will be necessary to comply with

local road traffic legislation as the machine is likely to

obscure the rear light units of the tractor.

Failure to comply with road traffic legislation may lead

to prosecution by local law enforcement agencies and

could also result in a road traffic accident.

11.0 MAINTENANCE

11.1 Safety

WARNING.

Never open the guards surrounding

the driveline or fan unless the PTO has been

disengaged, the engine has been stopped, the key

removed and the machine come to rest.

The fan and rotor will take approximately 3 minutes to

come to rest from operating speed.

11.2 Blades

When carrying out maintenance work on the blades,

wedge the rotor to prevent it from turning. Always

keep your hands away from the edges of blades

particularly new ones, as they are extremely sharp. A

leather glove will give some protection against minor

cuts.

IMPORTANT.

When replacing blade retaining bolts,

clean the threaded section and treat with a

threadlocking compound. The bolt should be

tightened to a torque of 150Nm (112lb/ft).

11.3 Hammers (404M & 505M only)

Hammers will wear with use and are designed to give

four different cutting surfaces before needing

8