22

22

7

Fault Correction

7.1

Error Messages

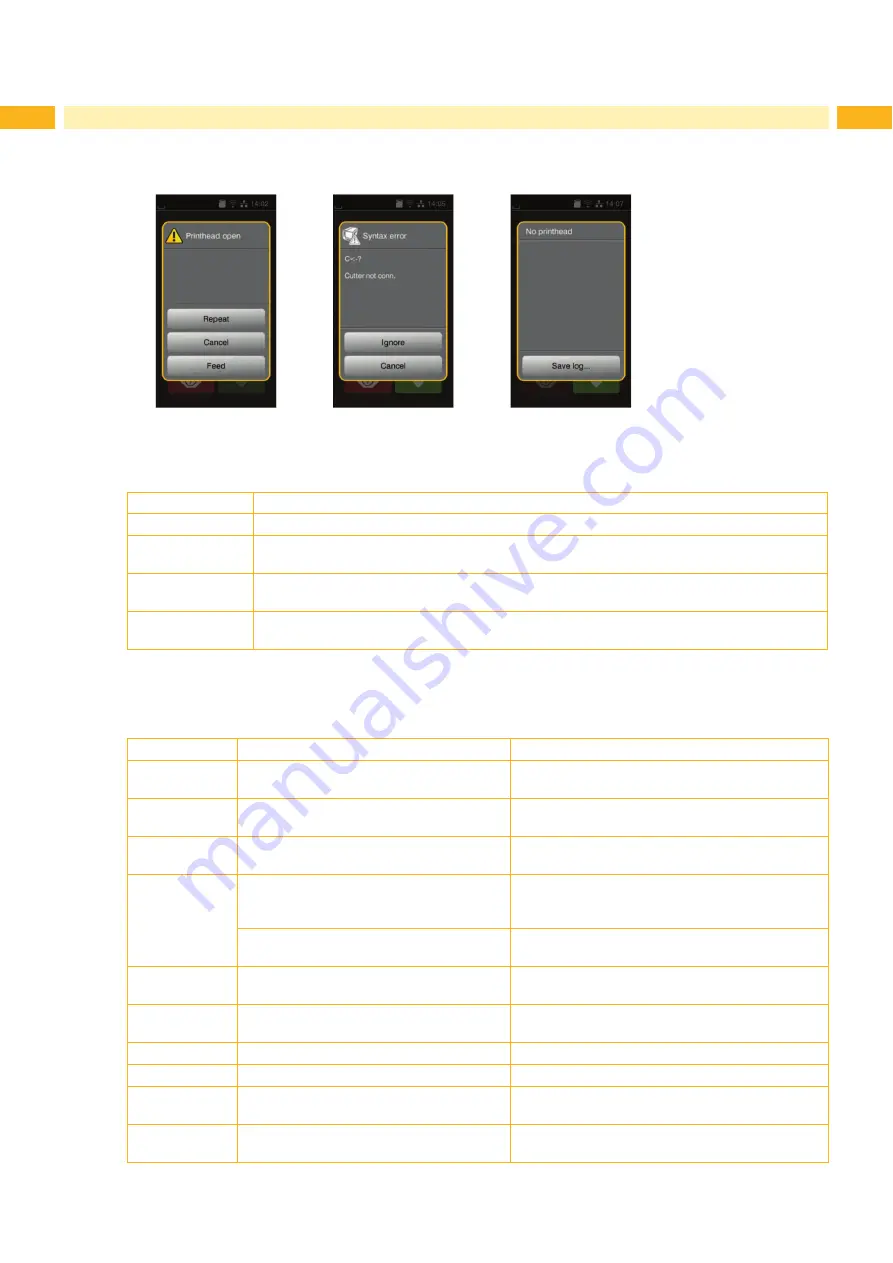

Should an error arise an error message will be visible on the display:

Fig. 18

Error display

The error treatment depends on the type of error

Z

7.2 on page 22.

The display offers the following possibilities to continue after an error has occurred:

Repeat

The print job will continue after clearing the cause of the error.

Cancel

The print job will be cancelled.

Feed

The paper feed will be synchronized. Thereafter the print job can be continued with the repeat

function.

Ignore

The error message will be ignored. The print job will continue possibly with limited

performance.

Save log

The error does not allow print operation.

)RUGHWDLOHGDQDO\VLVVHYHUDOV\VWHP¿OHVFDQEHVDYHGWRDQH[WHUQDOPHPRU\VRXUFH

Table 5

Possible options of error messages

7.2

Error Messages and Fault Correction

Error message

Cause

Resolution

Barcode error

Invalid barcode content, e.g. alphanumeric

characters in a numerical barcode.

Correct the barcode content.

Barcode too big

The barcode is too big for the allocated

area of the label.

Reduce the size of the barcode or move it.

%XIIHURYHUÀRZ

The input buffer memory is full and the

computer is still transmitting data.

Use data transmission via protocol (preferably

RTS/CTS).

Cutter blocked

The cutter cannot return to its home

SRVLWLRQDQGUHPDLQVLQDQXQGH¿QHG

position.

Switch off the printer and remove the material.

Switch on the printer and restart the print job or

change the material.

No cutter function

Restart the printer.

If error persists seek out the service department.

Cutter jammed

The cutter is unable to cut the labels but is

able to return into its home position.

Press

Cancel

and change the material.

Device not conn.

Programming addresses of non-existent

devices

Either connect this device or correct the

programming.

File not found

7KHUHTXHVWHG¿OHLVQRWRQWKHFDUG

Check the contents of the card.

Font not found

Error with the selected font

Cancel current print job and change the font.

0HPRU\RYHUÀRZ

Current print job contains too much infor-

mation (e.g. selected font/large graphics)

Cancel current print job.

Reduce the amount of data to be printed.

Name exists

'XSOLFDWHXVDJHRI¿HOGQDPHLQWKHGLUHFW

programming

Correct print job.