2. PRINTER SETUP

ENGLISH VERSION

2-17

2.9 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities

2.9 Media Sensor

Calibration, Self Print

Test, and Dump Mode

Utilities

This utility is used to calibrate the sensitivity of the Feed Gap/Black

Mark Sensor.

It is necessary to set the media sensors after the media is changed to

different type

.

1.

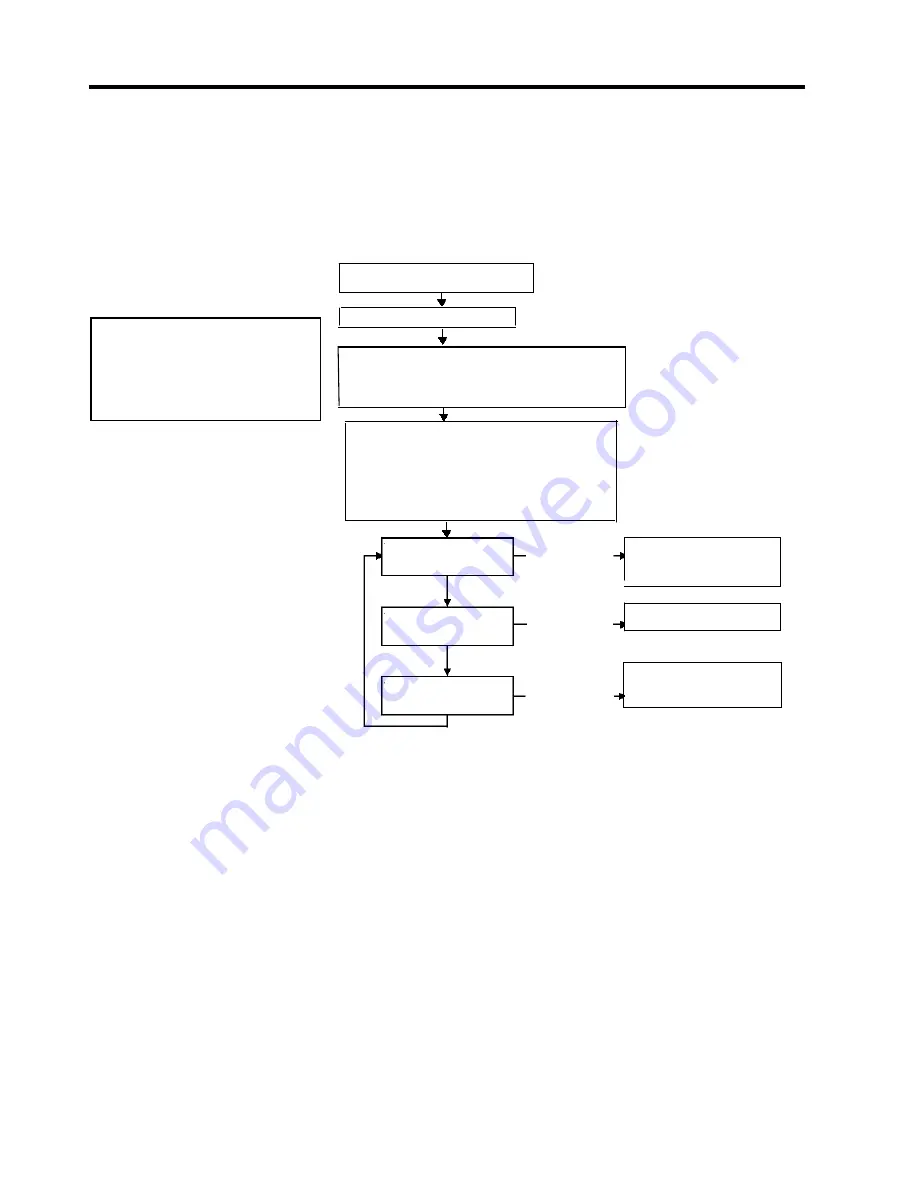

First, select the sensor to calibrate in the following procedure.

Turn on the printer power.

Open the Top Cover.

2.9.1 Media Sensor

Calibration

When the Indicator Lamp is unlit, hold down

the [FEED] Button for 5 sec. or more, and

release when the lamp lights up in green.

The Indicator Lamp repeatedly lights up in

different colours at approx. 1.5 sec. interval.

When the lamp lights up in the colour

representing the target sensor type, press the

[FEED] Button.

The Indicator Lamp is unlit.

(Reflective (Black Mark)

Sensor is selected.)

The Indicator Lamp is unlit.

(“No sensor” is selected.)

The Indicator Lamp is unlit.

(Transmissive (Feed Gap)

Sensor is selected.)

2.

Turn off the printer, load the media properly, and close the Top Cover.

Note

: Do not place pre-printed area above the media sensor, as doing

so disables a correct sensor calibration.

3.

To calibrate the Black Mark Sensor, align the sensor position with the

black marks on the media. (Refer to

Section 2.7

.)

4.

Press the [FEED] Button while turning on the printer.

The Indicator Lamp will light up in the following order:

Green (Flashing)

→

Red (Flashing)

→

Orange

(Flashing)

→

Orange

→

RED

→

Green

5.

Release the [FEED] button when the indicator lamp lights up in red.

The printer automatically feeds the media to perform a sensor

calibration.

Note

: If you failed to release the [FEED] button at the right timing,

retry from Step 4.

6.

To start the Online operation, turn the printer off, then on again.

NOTE

:

The sensor type used in the last print

job has been selected.

The factory default is the Feed Gap

Sensor.

The Indicator Lamp

lights up in

green

.

The Indicator Lamp

lights up in

orange.

The Indicator Lamp

lights up in

red

.

About 3 seconds.

About 3 seconds.

About 3 seconds.

[FEED] Button

[FEED] Button

[FEED]

Button

Turn on the printer power