EPP-1988-INT-7/13 4/20

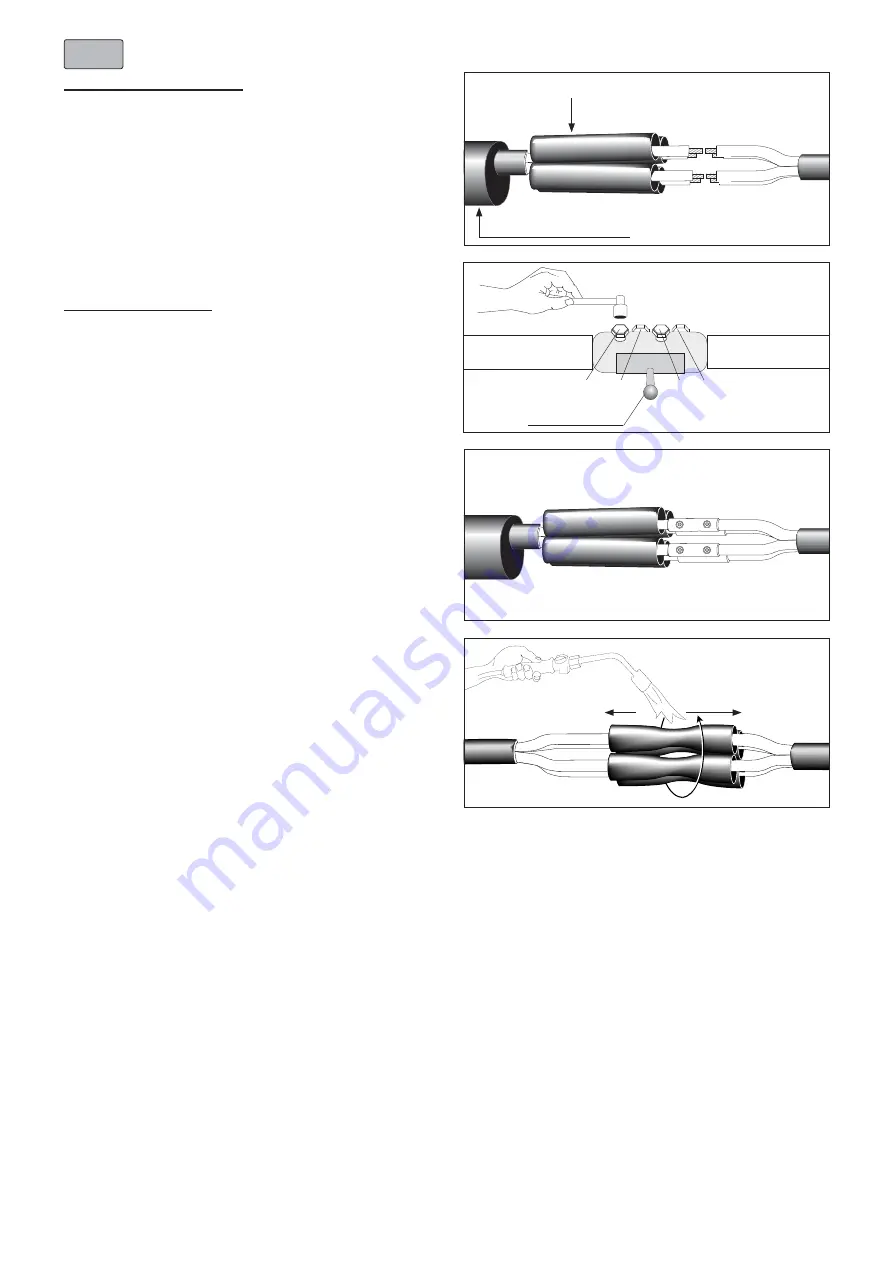

Position the inner insulation tubes centrally over the

connector area.

Shrink down the inner insualtion tubes, starting in the center

of the connectors, working towars the ends.

Before shaping the cores and laying them to each other,

allow the inner insulation sleeves to cool down.

5

Completion of the joint

Position the outer sealing sleeve over one of the cleaned

cable ends. Position the inner insulation tubes over the

long core ends.

Note:

Use only mechanical connectors supplied with the joint kit.

The screws of all connectors have to point to the outside, not

in the direction to the other cores.

The screws of the connector have to touch the outer wide

side of sector shaped conductors. If required sector shaped

cores have to be turned to the outside.

Conductor connection:

Wire brush the aluminium conductors. Hand tighten the

shear bolts so that the connector stays in place. For

connectors using more than one shear bolt per side, tighten

the bolts alternately and shear them off starting with the

outer bolts.

(see also sequence shown in the drawing).

Note:

When a cordless impact wrench is in use the tightening

intervals should be in the range of 2 seconds.

Avoid core bending on smaller cross sections by using a

support tool.

Note:

The sheared-off bolts should protrude the connector for not

more than 4 mm.

Clean and degrease the connector area and the core

insulation.

2

Inner insulation tubes

Outer sealing sleeve

4

3

Support tool

1

2

4

3

EN

NOTE -

When continuing, choose OPTION:

• OPTION

S:

Installation using

Outer Sealing Sleeve

-

see steps

6 S - 7 S

.

• OPTION

W:

Installation using

Wraparound Joint Sleeve

- see steps

6 W - 8 W

.