408-2681

2 of 5

Rev C

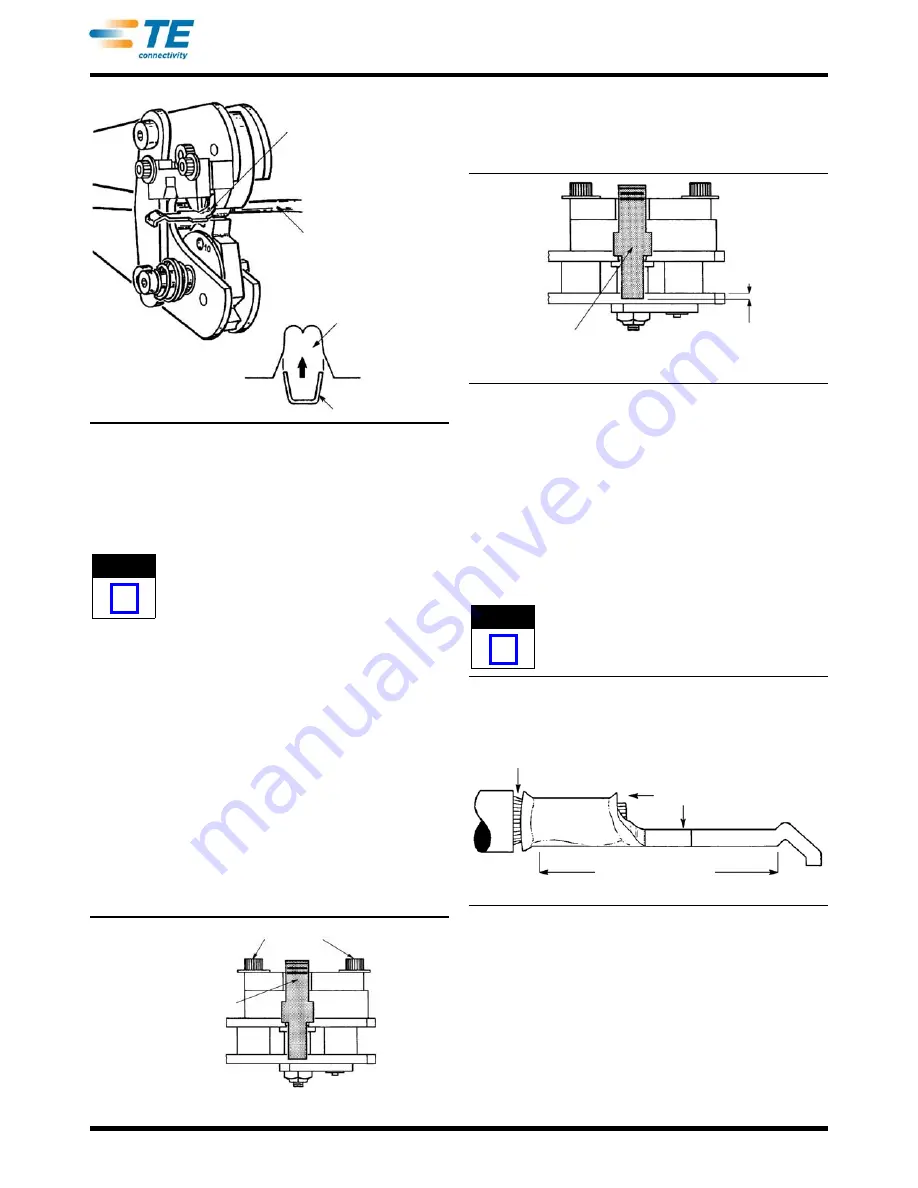

Figure 3

5. Crimp the contact by squeezing the tool handles.

Then tighten screws of the hold-down device and

contact locator. If the contact crimp is straight and

the wire barrel has not been damaged, the tool is

ready to use.

If the tool has been preset for wire size 10 AWG -

the smallest wire size-no further adjustment is

necessary, even though wire size 8 or 6 AWG is to

be terminated; the setting for wire size 10 will also

accommodate wire size 8 or 6. However, if the anvil

die is not set for wire size 10 and wire size 8 or 6 is

desired, then the anvil die should be set to the

appropriate wire size of either 8 or 6.

6. If the wire size marking is positioned for a wire

size other than desired, depress the anvil die

spring-loaded indexing pin and rotate the anvil die

until the desired size appears. Then release the

indexing pin and allow locator pin to snap into the

hole which locks the anvil die in place for the

desired size.

7. Open the tool head, and position the contact in

the nest, locating the outer end of the wire barrel

(wire-entry end) so that it extends from the nest

area between 0.76 to1.02 mm [.030 to .040 in.] as

shown in Figure 4.

Figure 4

8. Close tool head just enough to retain the contact;

then insert the wire into the wire barrel, making sure

the wire does not extend beyond the wire barrel.

See Figure 5.

Figure 5

9. Slowly squeeze the handles, making sure contact

remains aligned properly in the nest. It may be

necessary to open the handles slightly, allowing the

contact to be re-adjusted in the nest. Continue to

squeeze the handles to complete the crimp.

4. CRIMP INSPECTION

Inspected the crimped contact according to Figure 6.

Poorly crimped contacts can be avoided through

careful use of these instructions.

For a detailed inspection requirements, refer to

Application Specification 114-6032.

Figure 6

5. MAINTENANCE AND INSPECTION

5.1. Daily Maintenance

It is recommended that each operator of the tool be

made aware of-and responsible for-the following steps

of daily maintenance:

1. Remove dust, moisture, and other contaminants

with a clean brush, or a soft, lint-free cloth. DO NOT

use objects that could damage the tool.

Wire Conductor Flush

with or Recessed

Slightly in Wire Barrel

Wire Insulation Does

Not Enter Contact

Wire Barrel

Contact Must Retain

Proper Position in

Nest During Entire

Crimping Procedure

Configuration

of Nest

Wire Barrel

NOTE

i

Hold-Down Device and Contact Locator Screws

Torque of Contact

Fits in Slot

Wire Does Not Extend into

Contact Transition Area

Wire Barrel Extends

0.76-1.02 [.030-.040]

from Nest

NOTE

i

Wire Strands Visible Here -

Insulation Must Not Enter

Wire Barrel

Wire Strands Must Not

Extend Beyond this Area

or Above Wire Barrel

Crimp Inspection

Contact Must be

Straight in this Area