TDI TURBO

TWIN

FROM

TECH DEVELOPMENT

Publication

T1-932

Page

1

Issued May 20, 2016

1.0 GENERAL INFORMATION

This manual provides instructions for the installation and

operation of the TDI

T100-VE T

URBO

T

WIN

Air Starters. If

there are questions not answered in this manual, please

contact your TDI

T

URBO

T

WIN

distributor or dealer for

assistance.

The T100-VE starters are turbine driven starters with a

pre-engaged starter drive. The

T100-VE

starters have

applications ranging from 1800 CID (30 Liters) on diesel

engines and up to 18000 CID (300 Liters) on gas

engines. The

T100-VE

models are suited to operate

within a wide range of inlet pressures and ambient

temperatures. The engine size and parasitic loading will

determine the exact minimum pressure that will assure

reliable cranking.

The

T100-VE

starters are designed for operation with

compressed air or natural gas; materials used are

compatible with “sour” natural gas and marine

environments. Small amounts of foreign matter or liquid

in the air supply will not adversely affect

T100-VE

starters. As with all TDI starters, no lubrication is

required in the air supply.

Please review the rest of this manual before installing

the

T100-VE

air starter.

WARNINGS, CAUTIONS, AND NOTES

Certain types of information are highlighted in this

manual for your attention:

WARNING

- used where injury to personnel or

damage to the equipment is possible.

CAUTION

- used where there is the possibility of

damage to the equipment.

NOTE

- used to point out special interest

information.

NOTE

Throughout this manual, the term “air” is used to

designate the starter drive medium. Unless otherwise

stated, “air” means either compressed air or natural gas.

1.1 DESCRIPTION

The T100-VE features three basic subassemblies: a

unique two stage turbine motor section, an offset/spur

gear assembly and a pre-engage drive assembly.

The two stage motor section features greater stall torque

than a single stage turbine plus aerodynamic speed

control. This aerodynamic speed control helps protect

the

T100-VE

starter from damage caused by starter

motor over speed. In addition, a specially designed

motor housing module and low-mass rotors provide fail-

safe operation.

The

T100-VE

employs 9.25:1 ratio spur gearbox. This

low gear ratio allows the turbine motor to spin at low

speeds for long bearing life. At a typical 3000 rpm pinion

speed, the turbine is rotating at a low 27750 rpm.

A reliable pre-engaged drive delivers the torque to the

pinion. The pinion is translated out to engage the

engine's ring gear via the starter’s engagement piston.

Compressed air or natural gas is used to power the

T100-VE

through the inlet port. The air or gas is

expanded through the first nozzle or stators. The high

velocity gas impinges on the first stage rotor to yield

torque to the gearbox through momentum exchange.

The gas is further directed through the second stage

stators which impart additional torque to the second

stage rotor.

1.2 PRODUCT IDENTIFICATION

The starter nameplate which is attached to the turbine

housing contains the following information: model

number, serial number, part number, direction of rotation

and the maximum rated operating pressure.

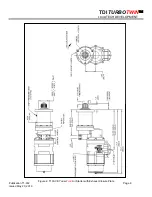

The directions of rotation are either right hand or left

hand rotation as shown in Figure 1. Right Hand rotation

is defined as clockwise rotation as viewed from the

pinion end of the starter, and Left Hand rotation is

counter clockwise rotation viewed from the pinion end of

the starter.