- 15 -

TC1631R/S

User's Manual

Rev. 1.6

Optical Loopback Test

At any time you may use a short optic cable to loopback the unit's Optic "TxA" to "RxA" or "TxB" to "RxB"

(dual optic models only). The "SYNC" LED on the front panel should light (solid) when a good optic signal

is received. This test verifies the optic transmitter's function as well as the receiver's. Upon successful

completion of this test, proceed to the Remote Loopback Test.

Remote Optic Loopback Test

1.

Connect a second TC1631R/S unit. As with the first unit, follow the bench test steps on the previous

page. When you have completed the Local Loopback & Optical Loopback tests for the second unit,

proceed to the next step.

2.

Remove the optical jumper cable from the local unit's "RxA" and connect it to the second unit's optic

"RxA." Add a second optical jumper cable to connect the local unit's "RxA" to the second unit's "TxA."

3.

Verify that both TC1631R/S units have the same Line Code and Line Length settings.

4.

On the local TC1631R/S, slide SW1-1 (Remote Loopback) to the Down (On) position. The "RMTLB"

LED will momentarily flash until it receives the remote optical signal, then it should be lit, indicating that

the unit is in RMTLB mode. (Note, other LEDs might flash for about three seconds, but will settled down

to their normal state.)

5. The "PWRA and/or PWRB," "Vcc," "Rx-A," "SYNC," "RMTRD," and "LOCRD" LEDs on the remote

TC1631R/S's front panel should be lit, as well as on the local unit.

6.

Make sure the "TERM" LED on the tester is lit, and that the tester is in the "RUN" mode. The tester should

indicate a "SYNC" signal.

7.

If any other LEDs illuminate or flash on the unit, make sure that all DIP switches on both of the TC1631's

are in the correct position, then reset the BERT tester. You should not see any bit errors.

8.

At this point, both units tested will have passed all electrical and optical tests and will have been verified

that they are functioning properly. When done, return SW1-1 to the Up "Off" position. Proceed to the

next TC1631 unit to be tested or begin verifying other equipment and cabling in your application (if you

have not already done so).

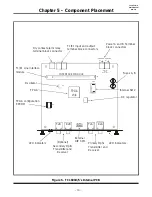

Remote Optic Loopback

IN

IN

Optic RxA

Optic RxA

Optic TxA

(Optical Redundant Models Only)

Optic TxA

Optic RxA

Optic RxA

Optic TxA

Optic TxA

T1/E1

BERT

Tester

Remote Optic loopback

Remote TC1631

Local TC1631

OUT

OUT

T1/E1 Line

Interface

T1/E1 Line

Interface

Local Optic Loopback

IN

Optic RxA

Optic RxB

Optic TxA

Optic TxB

T1/E1

BERT

Tester

Local o

loopback

ptical

(Optical redundant

models only)

OUT

T1/E1 Line

Interface